The Impact of Voltage Unbalance

If you are using three-phase systems, you should be aware of unbalanced voltages, one of the most common electrical power issues for industrial plants. The chances of your plant having imbalances are high when you do not have measures in place to prevent them. Catching imbalances before they cause severe damage to your equipment is ideal.

Below, find out what voltage unbalances are, what causes them, and how you can prevent and test for them to protect your electrical systems.

What Is 3-Phase Voltage Imbalance?

A three-phase power system is balanced or symmetrical when the three-phase voltages and currents have the same amplitude. An unbalanced system means the phase voltages are unequal.

This imbalance measures the difference between voltage phases in a three-phase system. This electrical power issue is common in industrial power plants or any plant that runs large machines with powerful motors.

Experiencing voltage imbalances can impact numerous aspects of your operations, including motor efficiency, costs, and damages.

What Causes Unbalanced Voltages?

ANSI C84.1 states: Electrical supply systems should be designed and operated to limit the maximum voltage unbalance to 3% when measured at the electrical meter under no-load conditions. This means it’s the responsibility of the user to verify the balance condition of their own plant’s voltage.

When a voltage is unbalanced, it is often because of system load distribution. These imbalances can occur at any point in a system, and unbalanced power systems can happen for many reasons.

Here are some of the most common causes of unbalanced voltages:

- Lack of symmetry in transmission lines

- Large single-phase loads, like arc furnaces or welders

- Faulty power factor correction capacitor banks

- Open delta or wye transformers

- Low torque output causing mechanical stresses

- High current in three-phase rectifiers and motors

- Current unbalance flowing in neutral conductors

- Faulty operation of power factor correction equipment

- Unbalanced or unstable utility supply

- Unbalanced transformer bank supplying a three-phase load that is too large for the bank

- Unevenly distributed single-phase loads on the same power system

- Unidentified single-phase to-ground faults

- Loose, corroded, pitted connectors or contactors

Even plant conditions can cause or contribute to voltage unbalance. For example, overloaded transformers, malfunctioning power factor correction devices, cyclical controls, and detuned reactors can all lead to imbalances. Even what is happening at the plant next door or farther up the power line could affect the voltage unbalance at your facility.

Effects of Voltage Unbalance

Voltage unbalance can be damaging to motors. A difference in phase voltages causes circulating currents in three-phase motors, resulting in a current unbalance of six to 15 times higher than the voltage unbalance. The extra current contributes to increased motor heating, which can be severe with a large enough unbalance. This higher motor temperature degrades the surrounding insulation, shortening the motor life and leading to motor burnout.

Other effects of unbalanced current and voltage include increased pulsation, mechanical stress, vibration, and losses. Additionally, maintenance issues like worn contacts and loose connections are common. These issues can cause a motor to operate loudly, run at elevated temperatures, and fail prematurely.

Further, the voltage unbalance will throw off the proportion of the locked rotor winding current, which is already relatively high, full load speed will be slightly reduced and torque will be reduced. If the voltage unbalance is great enough, the reduced torque capability might not be adequate for the application and the motor will not reach its rated speed.

NEMA standard MG-1, states that polyphase motors shall operate successfully under running conditions at rated load when the voltage unbalance at the motor terminals does not exceed 1%. Further, the operation of a motor with above a 5% unbalance condition is not recommended and will probably result in damage to the motor.

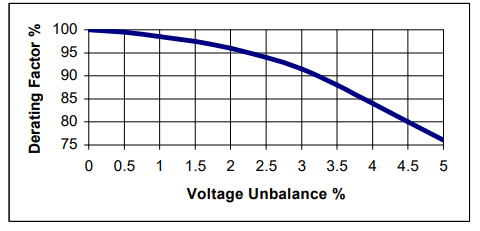

Although generally not desirable, another corrective action may be to derate a motor. When voltage unbalance exceeds 1%, a motor must be derated for it to operate successfully. The derating curve, shown below, indicates that at the 5% limit established by NEMA for unbalance, a motor would be substantially derated, to only about 75% of its nameplate horsepower rating.

Voltage unbalance can be damaging to the 3-phase DC converters used in variable frequency drives (VFD’s). Problematic variable frequency drives (VFD) that have nuisance-tripping, which show all the signs of circuit overload, even though measurements show otherwise, may have unbalanced phase currents. VFD line currents may become very unbalanced because of excessive current in one or two phases. This happens even though the average current of the three phases is well below the VFD’s current rating.

The front end of VFD’s uses an arrangement of high-power diodes to convert the 3-phase AC input power to create the DC bus as a reservoir for the power inverter section. The current through the input rectifier section is drawn in pulses. Ideally, the current flow through each diode is equally divided, however, voltage unbalance supplied to the input of the VFD causes unequal power through the individual diodes resulting in premature and frequent failure of the power diodes. The unbalanced output of the current diodes will create increased harmonic content. As the output pulses become more unbalanced, triple current harmonics will also increase.

Why Is This Important?

The most apparent reasons to care about voltage unbalance are decreased motor efficiency and performance — both of which affect your company’s profitability. Any given motor’s efficiency will vary, depending on factors such as the type of application, the load, and the supply voltage.

Operating on a power supply with a larger voltage unbalance will increase the I2R losses — that is, current squared times resistance — in the rotor and stator, meaning more of the supplied power will be converted to heat and less to work. The motor will run hotter and, consequently, less efficiently. Note that increased rotor losses will increase “slip,” so the motor will turn a little more slowly and do less work in a given time.

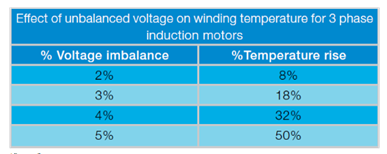

The basic Arrhenius equation states that the chemical rate doubles for each degree C increase in temperature. By applying this equation to the motor’s insulation it’s easy to see that any increase in temperature will dramatically reduce motor life. The following table shows the effects of winding temperature resulting from voltage unbalance.

As imbalances damage your equipment, your plant will experience downtime since the motors are not running as efficiently as they should be. In addition to the money lost during downtime, your damaged motors will require costly replacements or repairs

How to Prevent an Unbalanced Power System

To prevent voltage unbalance, the loads need to be equally distributed across the phases of a panelboard. When one phase becomes more heavily loaded than the others, the voltage on that phase will be low, resulting in an unbalance. Even distribution of your loads helps prevent one phase from getting overloaded.

Understanding the causes of an imbalance helps you and your technicians look for the signs and work to prevent them. The best way to prevent imbalances is to test for voltage unbalances and determine what could be causing them. Even if there is a slight imbalance somewhere in the system, testing for it now could help you catch it before the effects are damaging. The ATPOL III™ Energized Electrical Signature Analysis (ESA) Testing Instrument with accompanying ATPOL 8.0 software can quickly and accurately measure and calculate the voltage unbalance supplied to these industry workhorses as part of the routine energized motor tests that take less than 1 minute. The ATPOL 8.0 software calculates the % voltage unbalance and provides the appropriate voltage derating factor.

The portable ATPOL III™ can be connected quickly using a special connector to pre-installed ALL-SAFE© connectors or using removable CT’s and voltage probes in any easily accessible motor controller or disconnect. To provide added protection to the increasingly popular VFD’s they can even test the input power to these expensive controllers to ensure the voltage unbalance conditions that can lead to current unbalance through the rectifier sections are not present.

How to Calculate Unbalanced Current

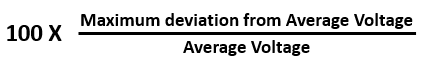

To manually calculate the percentage of an unbalanced voltage, you first need to determine the average current or voltage and the largest deviation. Then, you will divide the deviation by the average voltage and multiply that number by 100 to get your percentage.

The percent of voltage unbalance:

For example: V1 = 469

V2 = 478

V3 = 461

Average Voltage = 469.33 V2 has a maximum deviation 8.66667

% VUB = 100(8.66667/469.33) = 1.84%

The ATPOL is the ideal tool to add to your predictive maintenance toolbox for energized motor testing. Routinely performing an ESA motor test using ALL-SAFE PRO© allows plants to rapidly perform a complete inspection of the entire motor system.

The ATPOL III™ uses the motor’s voltage and current to access:

- The condition from incoming power

- The electrical and mechanical condition of the motor and unbalance

- Misalignment

- Bearing conditions

- Looseness

- Rubs of the load

- Anomalies in the process, such as cavitation

Portable measurements can be made easily from any motors that do not have all safes using portable, clamp-on, or flexible CTs.

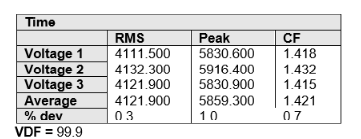

The ATPOL III™ performs a simultaneous data capture of all three phases of voltage and current to create the graphs, tables, and displays to use the quality of the power as a predictive maintenance tool necessary to place your equipment at the top of world-class facilities. Use V unbalance to predict premature winding insulation failure to determine reduced motor life caused by voltage unbalance.

Accurately Test Your Motors with ALL-TEST PRO

Motor testing is crucial to ensuring your equipment is operating properly and finding any errors or potential issues so they can be resolved. To ensure accuracy when testing your motors, use ALL-TEST products. Whether you are testing for voltage unbalances or conducting de-energized testing, our products can help you determine the status of your motor.

ATP knows motors. ATP specializes in energized and de-energized solutions for field testing. ATP products are field portable, lightweight, easy to use, accurate, and provide the earliest detection of potential issues, to keep your plant running efficiently and safely.