ADVANTAGES OF ESA SOFTWARE

ALL-TEST PRO On-Line III™ Software enables you to manage your plant’s motors efficiently and easily. Track, trend, and report on the condition of your plant’s motor assets. Share data to schedule maintenance and avoid downtime, unforeseen repair costs and improve worker safety. Trend assets and productivity and schedule maintenance based on facts and production schedules.

ALL-TEST PRO On-Line III™ Software is used to analyze and report both the electrical and mechanical condition of the entire motor or generator system. It delivers superior AC diagnostics for the evaluation of the health of the Stator Electrically and Mechanically, Rotor, Air Gap, and evaluates the entire driven load (belted, geared, bladed, etc.). It also provides excellent Diagnostics for DC motors, Generators and Transformers.

Comprehensive Database

The core of the MCA™ Software is a database that collects and organizes the nameplate information and individual test results from all of your motors and transformers. A powerful, integrated search functionality enables access to data across all companies and locations by motor voltage, horsepower/kW, RPM, etc.

Quality Control

Unlike other suppliers of motor testing equipment motor nameplate information is not required to evaluate the condition of the motor. Acceptance testing means YOU are in control of your motors program. The first test provides the baseline for future comparison.

Condition Monitoring

All test data can be trend-graphed for condition monitoring. Condition based monitoring allows you to see deteriorating conditions that will need to be rectified in the near future. Planning for repairs and avoiding unscheduled downtime saves you money and time.

ESA SOFTWARE CAPABILITIES

ESA software automates key determinations including:

- Line Frequency, Running Speed and Pole Pass Frequency

- Software automatically looks for patterns related to Stator Slot and Rotor Bar fault frequencies

- Automatic detection of Static or Dynamic eccentricity faults

- Evaluation of Incoming Power, including Harmonics

- Calculates Efficiency for AC Induction & DC Motors

- Calculates and identifies mechanical as well as electrical faults.

ALL-TEST PRO On-Line III™ comes standard with:

- Power System Manager Software

- Electrical Signature Analysis Software

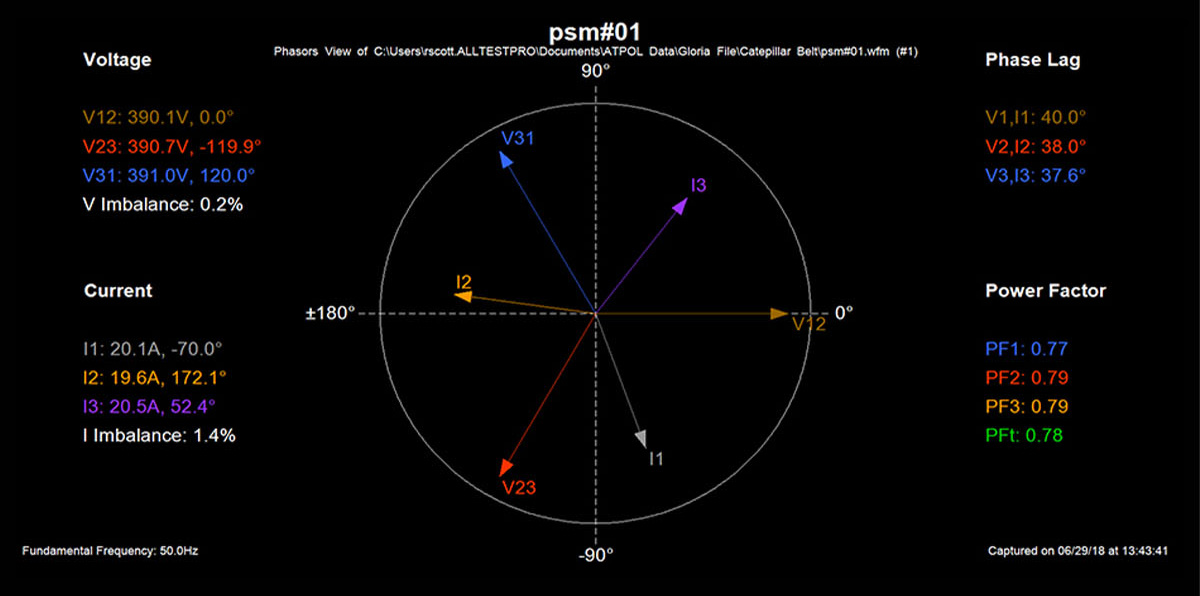

POWER SYSTEM MANAGER (PSM) CAPABILITIES

Software controls instrument function via Bluetooth interface and a laptop computer. No need for the user to stand in front of an energized electrical panel while monitoring the motor and collecting the data.

PSM software includes the powerful Test Plan Manager (TPM) module. Easily organize your collected test data with TPM. With prior setup, in a few button clicks, TPM allows your data to be easily imported in an organized way, exactly the way you want it.

PSM software allows test plans to be created, saved and distributed as necessary. The test data will automatically be saved onto the SD card, and transferred to their selected destinations from the SD card using the (PSM) software.

Define and clarify the project

- Automatically name and route the data to its intended destination.

- Automatically load the correct data setup for each test point.

- Include up to 9,999 Test Points for each test.

- Integrate the plan into the instrument and automate data collection for easy and accurate results.

- Optionally: Specify the Data Setup to use at each test point and manage the resources.

- Print and distribute the plan.

Integrate the test plan from your PC into your instrument

- Simply identify the Test Point and the instrument will perform the correct test.

- Speedy retrieval of test results with no errors or confusion.

- Distribute the plan to every instrument via SD Card.

- Distribute printouts of the plan to all personnel.

- Embed the test plan into the instrument, eliminating errors, and speeding up the data collection.

General power analysis will detect and capture power quality events such as fast transients (impulses) to 8us, voltage/current sags (dips), and swells.

- Track total harmonic distortion to the 65th harmonic.

- Record energy use (kWh), and log all power parameters: watts, va var, pf, etc.

- Data log RMS voltage and current over time (days/weeks/months) with cycle-by-cycle resolution.

- Display real time values in meter window – just like a multimeter.

- Display oscilloscope waveforms, harmonic spectra, phasors