Don’t Let Business Operations Stall

Many industries, including wastewater, steel, automotive and power generation industries, use electric motors to sustain production processes by converting inputs into mechanical power. Electric motor systems contain dozens, if not hundreds, of parts vital for business operation. Preventative motor testing measures are necessary to ensure your daily responsibilities continue.

Why Motors Burn Out: Preventive Measures

Without regular maintenance, electric motors are prone to wear and tear. Industries that use machines 24/7/365 creates stress on connections, fuses and bearings. Even new motors can suffer from power surges and can put you out of commission for weeks.

Electric motors typically showcase small, compact housings where heat becomes trapped. Excess vibration and fluctuating temperatures weaken insulation and motor hardware, increasing the chance of motor failure. Over time, motors also require thorough cleanings to eliminate debris.

Always pay close attention to the conditions surrounding electric motors. Humidity and moisture takes a toll on windings, fans and openings throughout the system. Electric motor testing removes the guesswork from troubleshooting individual components.

Motor Testing Importance

Professionals often think if a motor sounds like it’s working, then systems must be in order. However, this assumption is far from the truth. Motor failures can happen when your team least expects it.

In addition, not all winding faults start as ground faults. Instead, they can start as a weakness in the winding insulation system that may eventually fault to ground when the motor stops running.

Motor testing is integral to the success and efficiency of your business. ALL-TEST Pro instruments ensure that testing your motor is safe, easy, and dependable. Our capabilities for troubleshooting and predictive maintenance are a means of sustaining critical systems and achieving meaningful ROI.

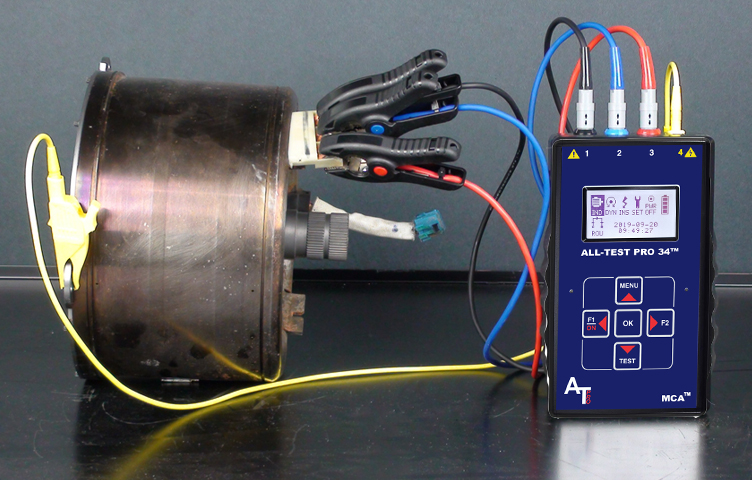

ALL-TEST Pro provides hand-held diagnostic devices for testing key motor components to fix small issues before they get bigger.

Why Traditional Megohmmeter Testing Isn’t Enough

Megohmmeter insulation testing only detects faults to ground. Since only a portion of motor electrical winding failures begin as ground faults, they will go undetected using this method alone. Moreover, surge testing requires the application of high voltages. This can be destructive when testing a motor, making it an unsuitable method for troubleshooting and true predictive maintenance testing.

ALL-TEST Pro devices offer more complete motor testing than any other options on the market. Our instruments go above and beyond normal testing equipment for accurate, safe, and fast motor testing. Motor testing using an MCA™ tool is very easy to implement, and the test takes less than three minutes. Save money and time by proactively detecting developing faults before they cause irreversible motor failures.

Issue | Meg-ohm Meter | Multi-Meter | ALL-TEST PRO 7 |

Ground Faults | |||

Internal Winding Faults | |||

Open Connection | |||

Rotor Faults | |||

Contamination |

Benefits of ALL-TEST Pro Devices

While traditional tools, such as a megohmmeter, are unable to detect small developing winding faults, our devices, such as the ALL-TEST PRO 7™, provide comprehensive, accurate information of the winding insulation, winding insulation to ground, and rotor.

Benefits include:

- Hand-held (usable in any environment)

- Provide 6+ Diagnostic Readouts (opposed to current Megohmmeters with only 1)

- Easy to Operate

- Responsive Customer Support

Deenergized (MCA™) vs Energized (ESA)

MCA™ Deenergized Testing

MCA™ is a non-destructive deenergized test method to assess the health of a motor from the Motor Control Center (MCC) or directly at the motor, providing immediate and complete information on the status of the stator, rotor, connections, contamination, and insulation to ground.

ESA Energized Testing

Electrical Signature Analysis (ESA) is an energized test method where voltage and current waveforms are captured while the motor system is running, providing valuable information for AC induction and DC motors, generators, wound rotor motors, synchronous motors, machine tool motors, and more.

Motor Testing With ALL-TEST Pro Devices

Using hand-held devices from ALL-TEST Pro is simple with our patented technology displaying onscreen instructions. Select models are optimized for voltage readings across induction, synchronous and single-phase motors and attach via included clips and push-pull connectors. Browse our list of motor testing products to find a compatible device for your current system.