Switch Language:

- English

- Español (Spanish)

- 简体中文 (Chinese (Simplified))

- Français (French)

- Deutsch (German)

- Indonesia (Indonesian)

- Italiano (Italian)

- Português (Portuguese (Brazil))

- 日本語 (Japanese)

- ไทย (Thai)

- Türkçe (Turkish)

- Tiếng Việt (Vietnamese)

- العربية (Arabic)

- 한국어 (Korean)

- Polski (Polish)

- Dansk (Danish)

- हिन्दी (Hindi)

- Svenska (Swedish)

- Punjabi

Results Matter

Our motor testing devices save companies time and money. Read our case studies to see how ATP can help your business.

Case Studies

- All

- AC and DC Motors

- Auto

- Energy

- ESA

- Facilities Management

- Food

- Manufacturing

- MCA

- Steel

- Water

Energized Motor Testing Reveals Improper VFD Settings

The Company Easy Tool is an Italian Condition Monitoring Solutions Provider with service and support representatives in Italy. Easy Tool, located in the town of Fabriano, in the province of […]

Proactive Motor Testing Protects Ethanol Plant

Ethanol has been a clean-burning fuel used in the United States since the 1850s. Ford’s Model T automobile was designed to run on ethanol, and while ethanol was banned during […]

Rotor Bar Fault Maintenance Issue: Vibration Sensor Alert

A 398 KW MV motor that runs a blower fan in a cement plant was showing strange behavior. The vibration equipment indicated vibration amplitudes that became chronic with the passage […]

Motor Bearing Mechanical & Electrical Vibration Testing

Preface A large majority of rotating equipment rely on Rolling Element Bearings (REB) for continued successful operation. Functionally Rolling Element Bearings carry the load of the shaft, internally position the […]

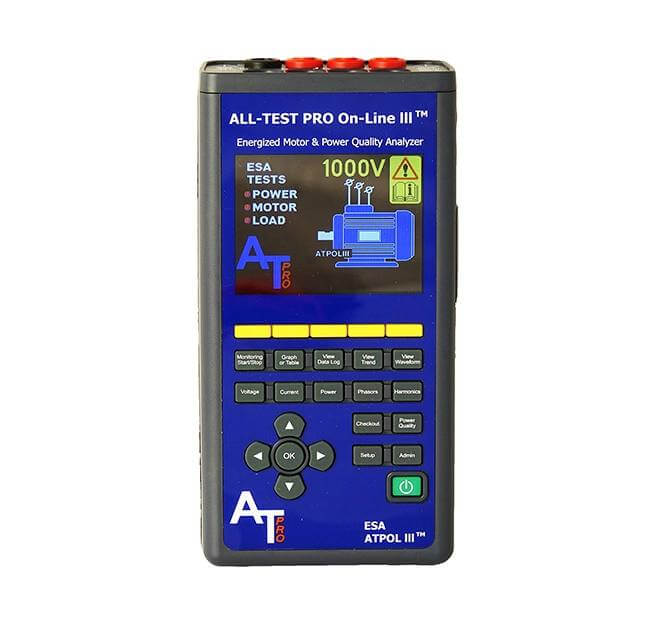

Online Motor Testing with Electrical Signature Analysis

On-Line Electrical Motor Testing 101 Electrical Signature Analysis (ESA) is an on-line test method where voltage and current waveforms are captured while the motor system is running and then, via […]

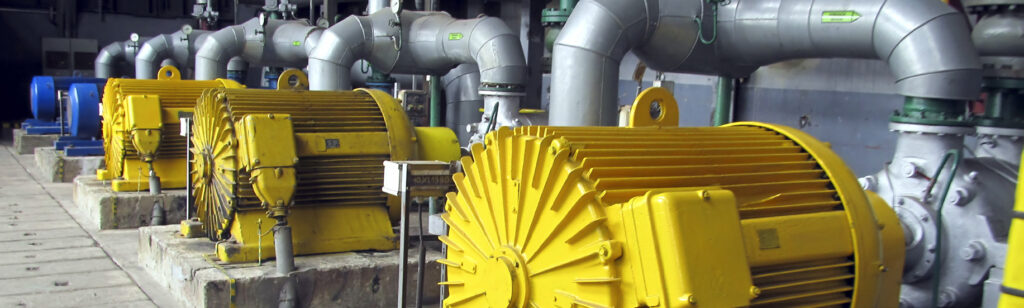

Motor Condition Monitoring Reduces Energy Use In Municipal Utility District

A municipal utility district (MUD) in Texas began working with a company that specializes in motor reliability and power quality testing for the water/wastewater industry. At a MUD board of […]

Dynamometer Fault Diagnosed at Automotive Plant

Description Location: Mid-Western Truck Transmission Manufacturing Facility Dynamometer Motor: 200 Horsepower, Special Motor and Dynamometer Drive, 480 Volts Effected Systems: Final In-Process Inspections, 8% of capacity effected Failure Cost: >$125,000 […]

Synchronous Motor Rotor Fault Analysis

A large 8,000 HP, 13.2 kV, 200 RPM synchronous motor that operates a reciprocating compressor at a chemical plant tripped on ‘short-circuit’ warning during startup, using a General Electric Multilin®, […]

Power Plant Uses Electrical Signature Analysis for Performance Assessment

One nuclear power generating facility, located in the Northeastern United States, relies on four vertical service water pumps to feed water to a heat exchanger which cools the sealed ultrapure […]

Generator Phase Unbalance Diagnosed, Saves Company 1M

Description Location: Vermont Yankee Nuclear Power Plant Equipment: 50 HP, 3600 RPM, 480 Volt, Open Drip Proof, Cooling pump motor Effected Systems: 500 MW Generator Bearing Cooling Failure Cost: $1,000,000 […]

Steel Mill Predictive Maintenance

The Company Gerdau is one of the largest producers of steel and steel recycling in North America, with an annual manufacturing capacity of approximately 10-million metric tons of steel products. […]

Automotive Manufacturer Compares In-House Reliability Team vs Service

The Company A large automotive manufacturing facility in the Midwest scheduled a planned shutdown in July 2018. Having been in operation since the early ‘80s, the plant spans over 3 […]

Stator Looseness Diagnosed by Electric Motor Testing Tool

Initial Findings A 6.6 kV motor that is used to cool the temperature of gas after going through a gas phase polymerization process at a Petrochemical plant was experiencing abnormal […]

Water Treatment Plant PdM Saves Facility Time & Money

A work order was issued by a Waste Water Treatment Plant Technician requesting electrical support due to a failed floating agitator. The breaker had tripped and the mixer is a […]

Electric Motor Diagnosis: Loose Power Connections

The Company A major automotive manufacturer, located in North America with four manufacturing plants, utilizes MCA™ (Motor Circuit Analysis™) to keep their operations running. The Application A conveyor motor […]

EV Reliability and Maintenance

EV shop and Maintenance talk with Dr. Mark Quarto from Quarto Technical Services Electric vehicle (EV) powertrains are much simpler compared to traditional combustion engines. These motors do not require […]

VFD Troubleshooting Case Study: Motor Test Reveals Damaged VFD

Easy Tool, a Condition Monitoring Solutions Provider in Italy, works with a paint production facility in Ancona, a city along Italy’s Adriatic coast. This paint producer has worked with Easy […]

Motor Current Signature Analysis on Gearbox Motor

Introduction Noise and vibration was investigated on a 7.5 horsepower, 1750 RPM, 575 Vac motor and gearbox using the ALL-TEST PRO™ OL (ATPOL) motor current signature analyzer. One set of […]

Pulse Width Modulated Motor Drive Fault Detection Using Electrical Signature Analysis

Industry’s use of Motor Drives for AC motors continues to grow and the Pulse-Width Modulated drive (PWM) has become the common industry standard for low to medium horsepower applications. As […]

Motor Testing: Which Road Will You Take?

Introduction Allison Transmission, General Motors Corporation is the world leader in design, manufacture and sales of commercial-duty automatic transmissions, hybrid propulsion systems, and related parts and services for on-highway trucks, […]

Steel Mills Increase ROI With Energized Motor Testing

If a steel mill was at risk of losing $5,000 for every minute of unplanned downtime, it would be no surprise to see that steel mill implement a preventive maintenance […]

Municipal Utility District Prevents Downtime With Acceptance Testing

The Companies Since 2008, a Municipal Utility District (MUD) in Texas has worked with Less Watts, Inc., a company that specializes in motor reliability and power quality testing for the […]

Predictive Maintenance in Manufacturing Case Study

A large, well-known automotive manufacturer compared in-house and third-party motor testing services at one of their facilities. Guess which one saved the most time and money? An automotive manufacturer planned […]

White Papers

- All

- AC and DC Motors

- ESA

- MCA

Improve Electro-Mechanical Reliability Using ESA

Figure 1. Common motor faults (CF=Center frequency, RS = Running Speed, LF=Line Frequency) Electrical Signature Analysis (ESA) is a predictive maintenance (PdM) technology that uses the motor’s supply voltage and […]

What is 3 Minutes of Motor Testing Worth to You?

The Company A motor distributor in the Netherlands provided a 17 Kilowatt, 400-Volt motor to a local hospital in 2015. The hospital rented a portable crane to install the motor […]

Rotor Bar Fault Maintenance Issue: Vibration Sensor Alert

A 398 KW MV motor that runs a blower fan in a cement plant was showing strange behavior. The vibration equipment indicated vibration amplitudes that became chronic with the passage […]

Electrical Signature Analysis vs Vibration Analysis

Abstract: It is well known that rotating machinery exhibit specific characteristics when faults cause the geometric centerline of the shaft to periodically move. For more than 70 years, Machinery Vibration […]

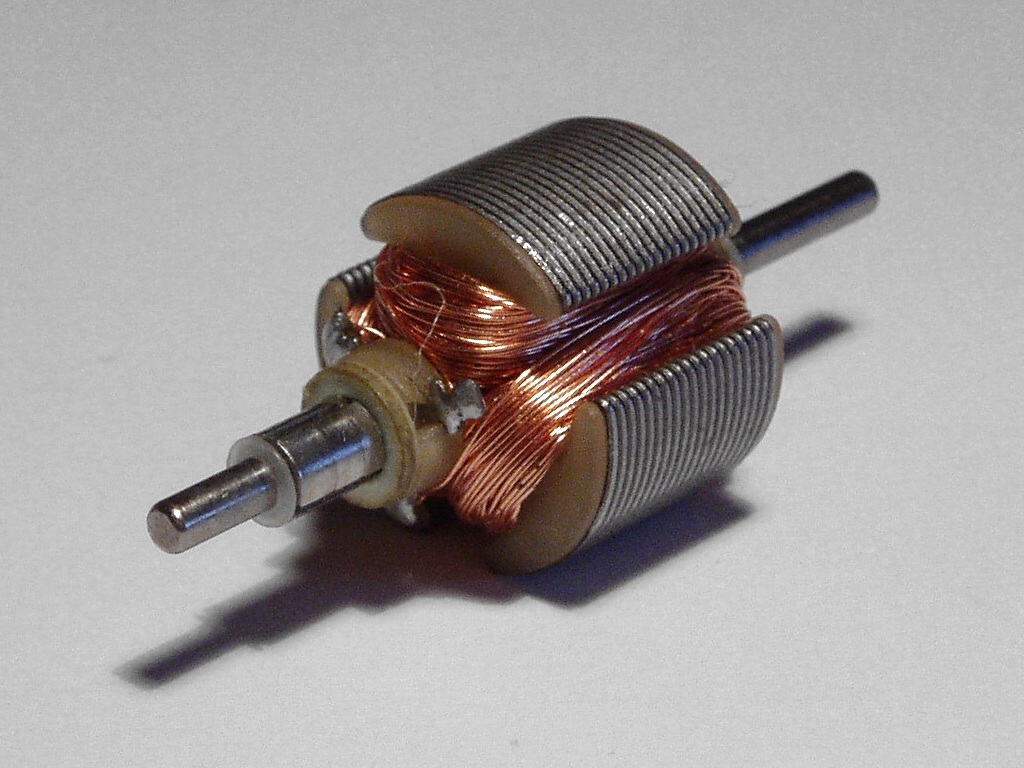

Rotating Machine Testing Guidelines

1. Overview 1.1 Scope This document describes a guideline for evaluating rotating equipment armature and field windings, rated from 1 horsepower (746 Watts) or greater, for winding shorts, phase unbalances […]

EV Testing: State-of-Health Verification Moves to the Forefront

Dr. Mark Quarto CTO – Quarto Technical Services After working for over 32 years in Electrified Vehicle technology, I have experienced most areas in the automotive development and engineering […]

Motor Testing Methods for Determining Efficiency & Reliability

Abstract This article discusses the financial impact of motor condition electric motor efficiency and reliability by reviewing a combination of Motor Circuit Analysis (MCA)and vibration techniques. Cost impacts on energy, […]

Predictive Maintenance Program: Implementing ESA

Why Predictive Maintenance? Predictive Maintenance (PdM) resulted from studies that determined that Preventive Maintenance (PM) programs are only effective for the 11 percent of machine failures that are age related. […]

Motor Bearing Mechanical & Electrical Vibration Testing

Preface A large majority of rotating equipment rely on Rolling Element Bearings (REB) for continued successful operation. Functionally Rolling Element Bearings carry the load of the shaft, internally position the […]

Online Motor Testing with Electrical Signature Analysis

On-Line Electrical Motor Testing 101 Electrical Signature Analysis (ESA) is an on-line test method where voltage and current waveforms are captured while the motor system is running and then, via […]

EV Reliability and Maintenance

EV shop and Maintenance talk with Dr. Mark Quarto from Quarto Technical Services Electric vehicle (EV) powertrains are much simpler compared to traditional combustion engines. These motors do not require […]

Motor Current Signature Analysis on DC Motor

Introduction Evaluation of a 10 HP, 1.0 SF, Ins F, 1750 RPM, 240 V, 33 Amp armature, 240 V, 1.23 Amp field, DC electric motor from the output of the […]

Eliminate Voltage Unbalance

Voltage unbalance degrades the performance and shortens the life of a three-phase motor. Voltage unbalance at the motor terminals can cause current unbalance that is far out of proportion to […]

Pulse Width Modulated Motor Drive Fault Detection Using Electrical Signature Analysis

Industry’s use of Motor Drives for AC motors continues to grow and the Pulse-Width Modulated drive (PWM) has become the common industry standard for low to medium horsepower applications. As […]

Motor Testing: Which Road Will You Take?

Introduction Allison Transmission, General Motors Corporation is the world leader in design, manufacture and sales of commercial-duty automatic transmissions, hybrid propulsion systems, and related parts and services for on-highway trucks, […]

Motor Circuit Analysis for Energy, Reliability and Production Cost Improvements

Introduction With news reports quoting power brown-outs due to increased electric demand, methods for controlling energy costs are no longer a green option, but more of a survival strategy. Within […]

Predictive Maintenance Program: Implementing ESA – Part II

This is a follow-up to the article that was published in the Dec/Jan 2012 issue of Uptime. Abstract This is the second part of a series of articles discussing […]

Machine Monitoring and How ESA Technology Can Upgrade Your Plant’s Reliability

By: William Kruger, ALL-TEST Pro More than 300 million electric motors are used in infrastructure, large buildings, and industry globally. These motors account for about 2/3rds of the industrial power […]

Reducing Costs with ESA and MCA™ Technology

Managing Rotating Equipment More than 300 million electric motors are used in infrastructure, large buildings, and industry globally. These motors account for about 2/3rds of the industrial power consumption. Electricity […]

Lessons Learned from Modern Motor Testing

Author: Aaron Schnelle, Technical Support, and Richard Scott, General Manager, ALL-TEST Pro, LLC. The Company During the demonstration of an ALL-TEST PRO 5TM Motor Circuit Analysis instrument (de-energized motor […]

Motor Vibration Analysis Equipment: Vibration Monitoring vs ESA

Many people only notice problems with motors when the motor may physically shake, vibrate, overheat, or make an audible sound, before taking the proper action to fix the issue. Vibration […]

Motor Diagnostics: The Multi-Technology Approach

Introduction There has been a persistent misconception that there is a ‘magic bullet,’ in the form of a Condition Based Monitoring (CBM) instrument, that will provide all of the information […]