Water Treatment Plant PdM Saves Facility Time & Money

A work order was issued by a Waste Water Treatment Plant Technician requesting electrical support due to a failed floating agitator. The breaker had tripped and the mixer is a necessary asset in the treatment process. When Two craftsmen investigated, they found that two wire nuts/splices in the termination box had burned and it was determined that the motor suffered a winding fault using the standard test practices for the field. Preparations were discussed to utilize contractors in the removal of the platform, disassembly of the unit and to repair the set as needed.

Condition As Found:

• Tripped breaker that would not reset.

• Burned/open terminations and winding fault.

• Standard procedure is to replace failed equipment.

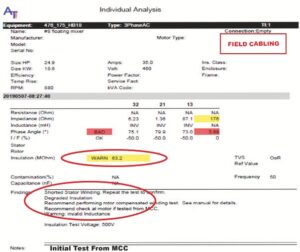

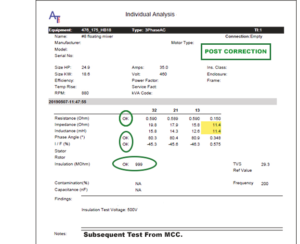

On their own accord, the craftsman requested that the AT5™ be employed before such a costly repair commence. Preliminary tests reported diminished insulation properties for the cabling between the MCC and the motor. A test performed at the motor itself returned a favorable result. Showing that the motor was in fact not failed and could remain in service.

Current Testing Results

• MCA™ Deenergized testing.

• Additional developing fault identified.

• Although aff ected by temp, motor receives a passing report

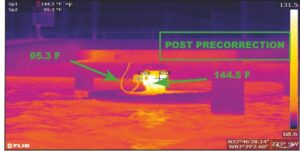

Termination repairs were made and the motor was tested for operation and returned to service. The motor cooling fan shroud was found to be completely full of debris which contributed to high temps and termination failure. This was cleaned resulting in much cooler motor temps. For reference, the last repair (bearings/impeller) for this type of asset was $6266 and the last motor rewind was $8600. Also, there is no spare available in their stores.