EV Reliability and Maintenance

EV shop and Maintenance talk with Dr. Mark Quarto from Quarto Technical Services

Electric vehicle (EV) powertrains are much simpler compared to traditional combustion engines. These motors do not require the normal service such as oil changes, spark plug, fuel and oil filter maintenance. Electric motors are generally reliable, long-lasting and easy to maintain. Even though electric motors require less maintenance they still need to be serviced according to the manufacturer’s suggested schedule. Normal issues that everyone focuses on is batteries but when it comes to the motors, there is a large gap in assessment and skill level required to diagnose electrical motors. “When I’ve had conversations with many automotive technicians and instructors over the years, most will quickly admit that they have minimal experience in knowing how to test, analyze, and diagnose EM systems. Although technicians are well versed in the diagnostic methodologies for traditional automotive powertrains, their experiences are a road less traveled in the electric powertrain space.”

Testing the EV Motor

The used and second owner EV market continues to elevate concerns about how technicians will confidently analyze and diagnose electric powertrain systems. Drive motor and generator (Electric Machines – EM) diagnostics and State-of-Health (SOH) analysis has moved center stage in automotive diagnostics and analysis. Automotive technicians have voiced a high level of interest in learning state-of-the-art analysis and diagnostic processes to aid in determining the SOH of an EM.

As Electrified Vehicles continue to age in the market, first owners of aged vehicles, secondary owners, and fleets are now asking the question “what is the condition of the drive motor and generator (stator and rotor) when determining the SOH of a vehicle?” Field technicians desire a method to diagnostic when targeting an electric powertrain failure condition. Specifically, OEM vehicle on-board diagnostics may not provide comprehensive analysis necessary for determining the health of an aged EM nor provide clarity of issues within the EM or its Power Inverter Module (PIM) system. Since the cost of an EM or PIM system can result in thousands of repair dollars, identifying and determining the root cause of the problem is essential. Labor time required to identify the root cause of a problem can be excessively time consuming adding more cost to the actual repair. If the systems are misdiagnosed, the part and labor costs escalate significantly. The aftermarket nor the OEMs have embedded EM SOH as part of a formal service testing process, as compared to the traditional gas engine (ICE or internal combustion engine).

If an automotive technician were queried on the causes for a traditional ICE misfire, variations in rpm, lean/rich condition, etc., it would be second nature for them to perform specific/ targeted testing. Some of these engine tests would include cylinder balance, compression, cylinder leak-down, vacuum waveforms, ignition system testing, etc. These tests are endemic and wired in the DNA of how automotive technicians test, analyze, and diagnose automotive powertrain systems. Compared to EV motors these same automotive technicians may be able to cite one or two types of tests but be completely unfamiliar with the additional testing elements that are used in EM analysis and the associated failure modes. Here in lies the root gap between the current level of EM analysis and diagnostics in the automotive service field.

Current State of EV Motor Maintenance and Troubleshooting

Automotive technicians are already overwhelmed with an immense number of courses they attend annually, just to stay current with traditional internal combustion engine (ICE) technologies. And, since ICE technology comprises most of the daily interaction for a technician, it is an onerous task for them (and the business owner) to justify allocating significant training hours to learn electric powertrain systems. However, the automotive market has reached an apex. The volume of Electrified Vehicle products in the market that are nearing or out of their warranty period are beginning to hit significant numbers. Global EV sales totaled about 7.2 million as of YE2019, a 57% increase over total EV’s sold as of YE2017. These volumes can no longer be ignored, especially by the automotive Aftermarket.

Automotive technicians are already overwhelmed with an immense number of courses they attend annually, just to stay current with traditional internal combustion engine (ICE) technologies. And, since ICE technology comprises most of the daily interaction for a technician, it is an onerous task for them (and the business owner) to justify allocating significant training hours to learn electric powertrain systems. However, the automotive market has reached an apex. The volume of Electrified Vehicle products in the market that are nearing or out of their warranty period are beginning to hit significant numbers. Global EV sales totaled about 7.2 million as of YE2019, a 57% increase over total EV’s sold as of YE2017. These volumes can no longer be ignored, especially by the automotive Aftermarket.

Currently, technicians rely heavily on pattern (recognition) failures of systems as a method of identifying the root cause of traditional (ICE) system failures. “Unfortunately, EM powertrain mechanical, electrical, and magnetic technologies are iterating so quickly that, pattern failures would be relegated to a less effective diagnostic approach. Without a firm technical foundation in EM technology, analysis and diagnostics will be a literal uphill battle for a technician. Learning EM analysis and diagnostic techniques requires significant training and experience, of which are a challenge for even seasoned diagnosticians, unless the analysis and testing equipment can scrub electrical and magnetic data to make the job of analysis and diagnostics an easier task.”

EV Motor Maintenance and Troubleshooting

The ALL-TEST PRO 33 EV™ instrument is the only tool made for testing the special permanent magnet motors and motor/generators used in electric & hybrid vehicles. With this innovative hybrid motor magnet tester, you can test magnet motors in vehicles from a single device that provides quick and precise diagnostic results.

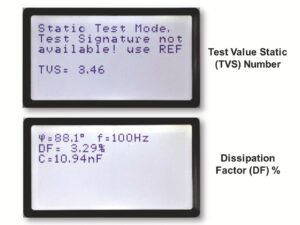

Mark’s rational for selecting the AT33EV: “The AT33EV scored the highest of five (5) MGU testing methodologies in a General Motors (GM) internal study that my team performed in 2011 to determine the prospect of MGU test instrument prognostic and testing capabilities. It also scored the highest in a study performed by an external electric motor testing supplier for GM when the study was replicated to ensure repeatability of test results and instrument performance. Therefore, the AT33EV is a superior test instrument for performing 3-phase EM testing and SOH analysis. One of the primary advantages of the AT33EV tool is its capability of testing an EM rotor without the requirement of rotation. In summary, the EM can be completely tested statically. For the technician, this means that testing can be accomplished with the High Voltage system disabled and no road testing is required – all testing can be accomplished in the service bay.”

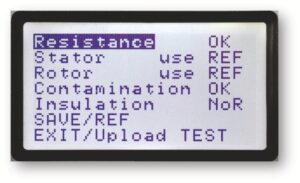

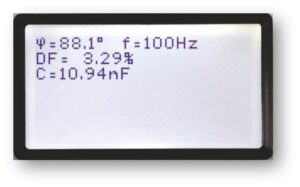

Testing parameters of the MGU SOH include direct current (DC), Resistance (Milliohms), Inductance, Impedance, Capacitance, Phase Angle, Current Frequency response, dissipation factor (contamination) and Insulation resistance. The AT33EV quickly troubleshoots or validates a systems motor connection and motor health.

Mark Quarto has been working for over 32 years in Electrified Vehicle technology. His experience includes most areas in automotive development and engineering. His work in electrical systems, vehicle electrification, propulsion and energy management lead him to start his own company where he teaches, mentors and consults to several OEM’s, remanufacturers and aftermarket companies in the EV marketplace. Some of Mark’s work includes: GM’s EV1, Chevrolet Tahoe/Yukon 2 Mode Hybrid, Chevrolet Spark, Volt and Equinox, Fuel cell demonstration fleet and other advanced concept vehicles. Quarto Technical Services is ALL-TEST Pro’s distributor for EV test instrumentation and consultation.

ALL-TEST Pro (ATP) has been providing safe, fast dependable motor answers for over 30 years with patented proven technology and equipment. ATP’s range of products is utilized in many industries such as manufacturing, food processing, water & waste, steel, utilities, aerospace, transport and more. All instruments are handheld, fast, portable, safe, and provide the motor & components condition and health as compared to traditional test equipment that generate measurements that need to be interpreted.