Online Motor Testing with Electrical Signature Analysis

On-Line Electrical Motor Testing 101

Electrical Signature Analysis (ESA) is an on-line test method where voltage and current waveforms are captured while the motor system is running and then, via a Fast Fourier Transform (FFT), a spectral analysis is done by the provided software. From this FFT, faults related to incoming power, the control circuit, the motor itself, and the driven load are detected and can then be trended for Condition Based Maintenance/Predictive Maintenance purposes. Our particular ESA instrument is handheld, portable and battery operated.

All ESA analysis systems require motor nameplate information of voltage, running speed, full load current, and horsepower (or kW). Additionally, optional information such as rotor bar and stator slot count, bearing numbers, and information for driven load components, such as blade count for a fan or tooth count for a gear box application can be entered for a more detailed and accurate analysis.

Energized on-line testing will provide valuable information for AC induction and DC motors, generators, wound rotor motors, synchronous motors, machine tool motors, etc. Since ESA is new to many people, the chart below illustrates ESA’s evaluation capabilities of the major components within a motor system.

![]()

Also performs Power Quality Analysis

- Power Quality Data Logging

- 3 channels of voltage and 4 channels of current logging

- Waveform capture of events ≥ ½ cycle

- Transient detection of events ≥ 8 microseconds

- Energy data logging · Harmonic analysis to 63rd (V & I)

- Phasor graphs · Pre-set and easy to use report templates

- Report energy savings using a before and after analysis function

On-Line Testing with Electrical Signature Analysis

ALL-TEST PRO OL II (ATPOL IITM)

- ESA

- Power Quality

- Sags & Swell

- Waveform Capture

- Energy Data Logging

Successful Applications for ESA

- AC/DC Motors

- Motor Drive Applications

- Generators/Alternators

- Traction Motors

- Machine Tool Motors

- Gearboxes

- Pumps and Fans

- For Reliability

- For Commissioning

- For Troubleshooting

ALL-SAFE PROTM connection box allows the technician to gather on-line testing data without opening up an energized panel.

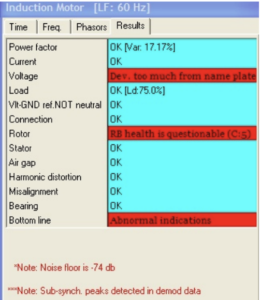

Automated Fault Detection

Summary example below is for an AC induction motor with squirrel-cage rotor

Data is collected via portable voltage and current probes or permanently installed connection boxes (ALL-SAFE PRO TM).

Collected data is then analyzed by provided software.

Alarms are pre-set and automatic report templates are provided for AC induction, Synchronous, and DC motors, plus Transformers.

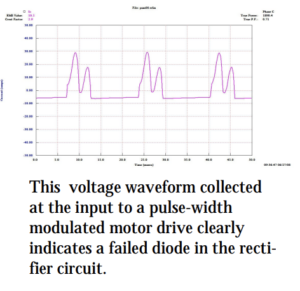

Excessive ripple on this voltage waveform indicates failing capacitors in this pulsewidth modulated motor drive. For more information about testing PWM motor drives using ESA email [email protected]

Analysis of Incoming Power

- Power Factor

- Current & Voltage unbalance

- RMS voltage to nameplate

- Voltage and Current Peak and Crest Factor

- Phase Impedance

- Power (Apparent, Real and Reactive)

- Total Harmonic Distortion (Voltage and Current)

Analysis of Power to the Motor

- Load to Nameplate

- THDF (Transformer Harmonic De-rating Factor)

- VDF (Voltage De-rating Factor)

- Product of THDF & VDF can be used for de-rating horsepower

- Demand Power

- Total negative, positive and zero sequence harmonics

- Efficiency for AC induction & DC motors

- * Can be used with the US Dept of Energy’s Motor Master+ software program for making repair or replace decisions. MM+ will also calculate payback if upgrading to energy efficient motor.

Analysis of the Motor

- Line Frequency

- Running Speed

- Pole Pass Frequency

- Rotor Health

- Air Gap (Static & Dynamic Eccentricity)

- Misalignment/Unbalance

- Stator Electrical

- Stator Mechanical

- Phase connection health

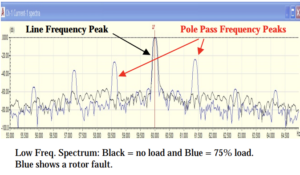

Analysis software provides a Compare Function where one spectra can be over-laid onto another for comparison purposes. The figure below shows a motor FFT spectra at no load and then at 75% load. The small peaks in Blue on either side of the large Blue peak are at what is called Pole Pass Frequency. These peaks are caused by multiple broken rotor bars.

Analysis of the Load

Mechanical System can be analyzed after information is entered into the software

- Direct Connected

- Gear Box

- Belted

- Fan blade

- Impeller

More Details about On-Line Analysis

One of the primary operations of the ATPOL II software is to perform a root-mean-square demodulation process on the power line carrier signal to provide a highly sensitive and selective means of extracting current signals from the motor load. This demodulation of the raw current signal removes the large line frequency component to permit a much improved signal-to-noise ratio for the components causing the modulation like running speed, belt passing, gear meshing, etc.

Numerous indications of performance are revealed within the time and frequency domains that provide the required information to determine the ‘health’ of the motor and the impact of the delivered load. This permits actually ‘seeing’ the true running speed, motor slip frequency, gear mesh frequency, drive train components, and gear rotational speeds.

To separate the various frequencies, a Fast Fourier Transform (FFT) is used and the resulting frequency spectra is displayed on the screen. The peaks in this spectra correspond to the rotational speeds of the different components in the machine. For example, in the case of a fan driven by an electric motor through a belt, the peaks correspond to the motor speed, pole passing frequency, fan speed, and belt speed. If a gear box is used instead of a belt drive, then spectral peaks will appear at the rotational speed of the gears and gear meshing frequencies.

The heights of these spectral peaks depend on two things; the overall current level to the motor, and the amplitude of the mechanical disturbances coming from the machine and sensed by the motor. The mechanical disturbances start as torque variations and end up in the motor as small speed variations that in turn cause the small current fluctuations being measured. For a constant overall speed condition, a change in the height of the fan speed peak, for example, would indicate a deterioration in the mechanical condition of the fan. By observing these changes, faults such as out of balance, misalignment, worn drive pulley or a bad bearing can be easily identified. Therefore, after taking data on a periodic basis, the frequency display is used to monitor electric motor driven machinery in order to provide an early warning of potential degradation.

The key difference between Motor Current Signature Analysis (MCSA) and Electrical Signature Analysis (ESA) is with MCSA the FFT is done on the current waveform only and not the voltage. This makes it more difficult to easily and quickly distinguish incoming power related problems from motor and driven load problems. With ESA you have both the current and the voltage FFT to see on the same screen. So it is just a matter of comparing the Voltage and Current FFT spectra to determine the source of the fault.

Generally, if the peak is dominant in the voltage spectra then the source of this peak is incoming to the motor. If the peak is dominant in the current spectra then the source is motor or load related.

ESA Fault Patterns

Type of Fault:

Stator Mechanical: CF = RS x Stator Slots with LF Sidebands

Static Eccentricity CF = RS x Rotor Bars with LF and 2LF Sidebands

Mechanical Unbalance/ Misalignment Proprietary algorithm is used

Dynamic Eccentricity CF = RS x Rotor Bars LF and 2LF Sidebands with RS Sidebands

Stator Electrical (Shorts) CF = RS x Stator Slots LF Sidebands with RS Sidebands

CF= Center Frequency RS = Running Speed LF = Line Frequency