Generator Phase Unbalance Diagnosed, Saves Company 1M

Description

Location: Vermont Yankee Nuclear Power

Plant Equipment: 50 HP, 3600 RPM, 480 Volt, Open Drip Proof, Cooling pump motor

Effected Systems: 500 MW Generator Bearing Cooling

Failure Cost: $1,000,000

Savings: >$1,000,000

A 50 HP, 3600 RPM, delta connected electric motor was installed and rotation checked on the Vermont Yankee generator bearing cooling pump. It was one of two motors and would only be brought into operation if the primary motor failed. When the primary failed, the motor was brought online. It was noticed that there was an 11% (p-p) current unbalance with a less than 0.5% voltage unbalance. The motor was also exhibiting a 120Hz vibration (electrical) and had an excessive operating temperature, although the peak current identified the motor as operating at 90% load.

Initial Readings

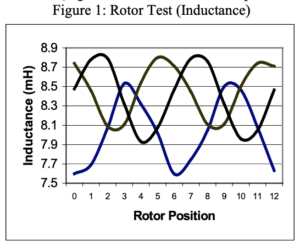

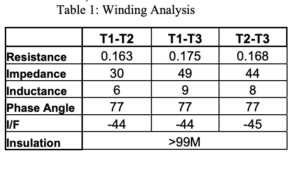

An ALL-TEST III™ was used to determine the phase unbalance, with results of 000, -016 and –016 (% unbalance) phase to phase when the rotor was shifted to the peak unbalance on each phase. Two additional motors of the same model and similar serial numbers were selected for review and tested using both the ALL-TEST IV PRO™ 2000 and ALL-TEST III™. The resulting phase unbalances and rotor tests were evaluated (Figure 1 and Table 1 are examples of the common results):

The unbalance was found to be striking, and related to the unbalanced current, vibration and heating of the motor. Possibilities were explored ranging from power quality to test equipment calibration. All were satisfactory.

Next Step

The motor manufacturer was contacted and noted that process changes were made at a particular location for larger concentric wound machines. In a motor of this size and speed, the first set of concentric coils (one phase) curls under the following phases, reducing the equipment’s winding appearance and mechanical strength. In order to combat that issue, the manufacturer made a decision to significantly increase the size of the first set of coils in their automated process (first phase) that also happens to be the furthest from the rotor. This allows the coil ends to appear without having to make post-winding modifications to the coils. No dynamometer testing, full load testing, or otherwise was performed on the motor design other than an applied voltage impedance test that ‘met design requirements.’ Electrically, inductance is directly impacted by distance from the rotor, number of conductors and dimension of the coil. The motor manufacturing process improvement caused the unbalance.

Motors from other manufacturers were evaluated and found to have balanced windings. However, several new motors were found to have rotor casting voids that would impact the motor’s ability to produce torque.

Vermont Yankee Nuclear has now implemented a program to test all incoming critical electric motors prior to acceptance using a combination of the ALL-TEST III™ and ALL-TEST IV PRO™ 2000.

Cost Avoidance

The generator would have had to shut down within two minutes of the second motor failure. The emergency generator shutdown may have caused damage to the generator bearings and an unplanned electrical outage. Cost avoidance was estimated at well over $1,000,000 through the detection of the fault. Subsequent detection of similar motor conditions through new and repaired motors has continued to justify the incoming test and inspection program.

Conclusion

New and repaired electric motors are not immune to defects. These defects may be the result of production/repair mistakes or design errors. A program of incoming inspection using both the ALL-TEST III™ and ALL-TEST IV PRO™ 2000 will identify these potentially costly failures prior to installation of the equipment.