Motor Vibration Analysis Equipment: Vibration Monitoring vs ESA

Many people only notice problems with motors when the motor may physically shake, vibrate, overheat, or make an audible sound, before taking the proper action to fix the issue. Vibration monitoring sensors have become more commonly used but sometimes do not find the true issue within the motor in time before further damage occurs.

Electrical Signature Analysis (ESA), a technology that assesses the circuitry of the components within the entire motor system (Motor Control Center (MCC) or Variable Frequency Drive (VFD)), cables and motors, is used in other types of motor vibration analysis equipment, such as the hand-held ALL-TEST PRO On-Line II™ (ATPOL II). ESA pinpoints early-stage motor faults often before they are more easily detectable.

This case study discusses the strengths and weaknesses of two different types of motor vibration analysis equipment in assessing and diagnosing a motor’s rotor damage.

The Backstory

Easy Tool is a Condition Monitoring Solutions Provider with service and support representatives in Italy. Located in the town of Fabriano, in the province of Ancona, Easy Tool represents ALL-TEST Pro instruments and performs regular condition monitoring services for a local paper manufacturer.

Every three months, a field engineer travels to the paper manufacturing facility to test their equipment, including fans, motors, rollers, and gear boxes. Data is collected four times throughout the year for trending and predictive analysis to support the paper manufacturer’s safety and equipment reliability programs.

In September 2016, Ettore Di Pasquale, Field Engineer, used a multi-technology approach to properly diagnose an issue with an induction motor.

The Motor Setup

A VFD-driven, 15-kilowatt induction motor was used to drive an industrial fan on a drying section hood of a machine that produces paper.

While the machine produces paper, this industrial fan extracts the fumes from the machine and sends them through a filter before releasing the exhaust out to atmosphere.

Vibration Analysis Suggests Motor Unbalance (but Electrical Signature Analysis shows otherwise)

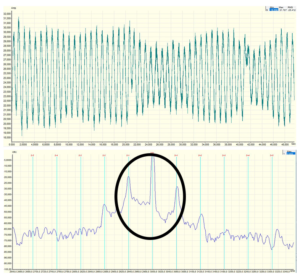

The initial vibration analysis showed high vibration values and a spectrum which could have been interpreted to be motor unbalance. Even though the first portion of the spectrum looked similar to an unbalance pattern, the Field Engineer knew to continue investigating.

Speed was measured with a strobe and showed that the revolutions per minute (RPM) had been changing very quickly – even though the VFD was set to run the motor at a fixed speed of 1,470 RPM. Seeing the speed of the induction motor change rapidly is indicative of broken rotor bars.

At this point, the Field Engineer continued with his multi-technology approach and performed an Electrical Signature Analysis with the hand-held ALL-TEST PRO On-Line II™ energized motor testing instrument to investigate the condition of the motor’s rotor bars.

Electrical Signature Analysis Confirms Broken Rotor Bars

Electrical Signature Analysis (ESA) is a motor diagnostic technology that uses the motors supply voltage and operating current to identify existing and developing faults in the entire motor system.

When in ESA mode, the ATPOL II™ evaluates the condition of incoming power, the control circuit, the motor itself, and the driven load.

The ESA of this induction motor showed significant variations in current when the motor speeds up, it draws more current; when it slows down, it draws less current. The large fluctuations in current varied about 30% because the motor was varying load due to speed variations.

.

.

Solving the Issue to Prevent Motor Failure and Keep Employees Safe

The Field Engineer reviewed his comprehensive analysis with the paper manufacturer’s predictive maintenance and reliability manager, and the suggestion was made to replace the motor. A new motor was promptly installed during a planned shutdown, and another vibration analysis was performed on the new motor to make sure it was working as intended.

Vibration analysis of the new motor showed that the vibration had significantly decreased. Where the original damaged motor had shown high values of vibration around 11 mm/sec., the vibration analysis of the new motor showed values around 0.35 (30x less vibration).

More importantly, the new motor was operating at a constant speed, ensuring the industrial fan could evacuate fumes from the paper production machine with the consistent air flow. Maintaining speed and air flow for fume suction meant creating a healthy and safe work environment for the manufacturer’s employees.

The Motor Vibration Analysis Equipment Conclusion

Lessons learned:

1. If the broken rotor bars had not been detected, the motor would have failed. Motor failure would have led to unsafe working conditions inside the manufacturing facility. Condition monitoring and Predictive Maintenance (PdM) programs are very important initiatives that every manufacturer should implement.

2. Motor vibration analysis equipment alone, such as vibration monitoring sensors, while very informative and important, do not always clearly identify motor faults. Vibration testing should be performed alongside Electrical Signature Analysis. It is critical to take a Multi-Technology Approach when checking the condition of your motors, as one technology is usually not ‘enough’ to properly diagnose motor health.

3. There are easy-to-use portable instruments, like the ALL-TEST PRO On-Line II™ (now ALL-TEST PRO On-Line III™) energized motor testing instrument, that can help you check the health of your motors. The ATPOL II™ is an invaluable monitoring and diagnostic tool that can help you see what is really going on with your equipment. Make sure you have the proper tools to support your condition monitoring program.

About All-TEST Pro, LLC.

ALL-TEST Pro delivers on the promise of true motor maintenance and troubleshooting, with innovative diagnostic tools, software, and support that enable you to keep your business running.

About SPM Instrument

SPM Instrument has over 40 years’ experience with machine condition monitoring, working with several industries in more than 50 countries to provide technical service, support, and training in condition monitoring practices.