Motor Condition Monitoring Device

AT34™

Deenergized Motor Circuit Analysis™ (MCA) Testing Instrument

Starting at $7,735.00 USD

The AT34™ is a hand-held, motor condition monitoring device that comprehensively analyzes the integrity of a motor’s inner components and trends that data in MCA™ condition monitoring software.

Interested in Leasing? Click Here

Features

- Hand-held & Lightweight (under 1lb)

- On-screen step-by-step testing instructions

- Tests take less than 3 minutes

- Trends motor condition with MCA Software

- Tests can be performed from over 1000′ away

- Remote firmware updates

*Note: Route feature only available with MCA PRO Software.

Capabilities

- Trend Motor Health with Condition Monitoring (with MCA Software)

- Comprehensively Evaluate AC Motors <1000V

- Portable & Battery-Powered

Software

MCA Software (Optional)

IMPROVE MOTOR RELIABILITY

The new AT34 empowers technicians to efficiently and accurately evaluate AC induction squirrel-cage motors (less than 1,000V) for abnormalities such as open connection, ground faults, internal winding faults, stator winding issues, contamination and rotor faults.

Initiated from the motor drive or motor starter, the AT34 uses Motor Circuit Analysis™ technology to evaluate the health of a motor in a non-destructive manner.

Use the AT34 whether you are in the field or on the shop floor – improving motor reliability, increasing technician and asset productivity, and reducing energy consumption.

Motor Condition Monitoring & Trending

In addition to troubleshooting functions, the AT34 is used as a motor condition monitoring device, to assess the integrity of a motor’s inner components over time to determine if a motor is going to fail.

Using proprietary TVS Technology, the AT34 allows users to conduct one simple, 3 minute test to create an overall ‘machine health’ condition value to be trended over time. Deviations and/or fluctuations in the machine health value indicate a motor problem to be investigated further.

Data is transferred via USB cable to a PC with MCA Software, for trending purposes, analysis, and generating reports.

Complete Motor Health Assessment

The electrical health of all motor components is evaluated, including, but not limited to induction windings, rotors and all associated connections and cables.

Patented Test Value Static™ (TVS™)

Test Value Static (TVS) technology uses a proprietary algorithm to create an overall ‘machine health’ value from a quick, 3-phase test that analyzes impedance, inductance, phase angle and current frequency, to trend over time.

Patented Dynamic Stator and Rotor Signatures™

Used to evaluate the condition of the stator and squirrel-cage rotor in a single test. Perfect for testing new and repaired motors prior to acceptance.

Issue | Meg-ohm Meter | Multimeter | AT34 |

Ground Faults | |||

Internal Winding Faults | |||

Open Connection | |||

Rotor Faults | |||

Contamination |

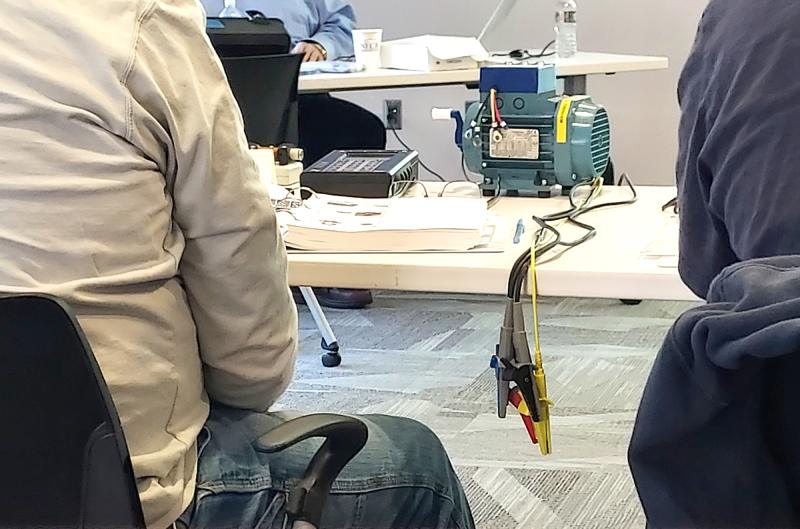

Motor Diagnostic Training

ALL-TEST Pro provides on-site and virtual comprehensive learning experiences that incorporate theory, new technologies, and practical field applications to educate attendees in the scope of motor diagnostics and comprehensive testing, including Motor Circuit Analysis™ (MCA™) and Electrical Signature Analysis (ESA).