ADVANTAGES OF MCA™ SOFTWARE

MCA™ software enables you to manage your plant’s motors efficiently and easily. Track, trend and report on the condition of your plant’s motor assets in one software program. Share data to schedule maintenance and avoid downtime, unforeseen repair costs and improve worker safety. Trend assets and productivity and schedule maintenance based on facts and production schedules.

ALL-TEST Pro’s MCA™ Software enables analysis, quality control, troubleshooting and predictive maintenance for complete deenergized motor testing. The software compliments the AT7™, AT7™ PROFESSIONAL, AT34™, AT34 EV™ and AT5™ to create a complete analysis package for monitoring and maintaining electric motors and transformers.

Our MCA™ Software’s intuitive analytics take the guesswork out of interpreting test results, including built-in diagnostic algorithms and trending as well as seven options for thorough, flexible report types.

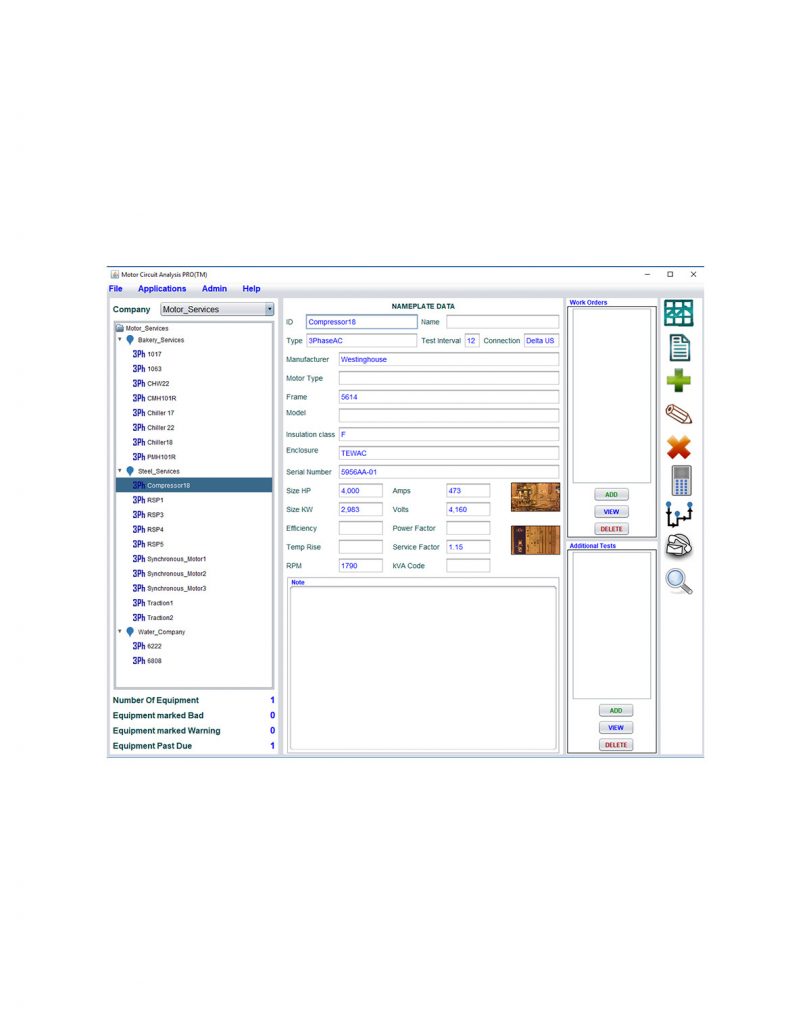

Comprehensive Database

The core of the MCA™ Software is a database that collects and organizes the nameplate information and individual test results from all of your motors and transformers. A powerful, integrated search functionality enables access to data across all companies and locations by motor voltage, horsepower/kW, RPM, etc.

Quality Control

Unlike other suppliers of motor testing equipment motor nameplate information is not required to evaluate the condition of the motor. Acceptance testing means YOU are in control of your motors program. The first test provides the baseline for future comparison.

Condition Monitoring

All test data can be trend-graphed for condition monitoring. Condition based monitoring allows you to see deteriorating conditions that will need to be rectified in the near future. Planning for repairs and avoiding unscheduled downtime saves you money and time.

MCA™ SOFTWARE FEATURES

Comprehensive Database

The core of the MCA™ Software is a database that collects and organizes the nameplate information and individual test results from all of your motors and transformers. A powerful, integrated search functionality enables access to data across all companies and locations by motor voltage, horsepower/kW, RPM, etc.

Evaluate New and Repaired Motors for Quality Control

Unlike other suppliers of motor testing equipment motor nameplate information is not required to evaluate the condition of the motor. Acceptance testing means YOU are in control of your motors program. The first test provides the baseline for future comparison.

*Requires MCA PRO™ Enterprise software only.

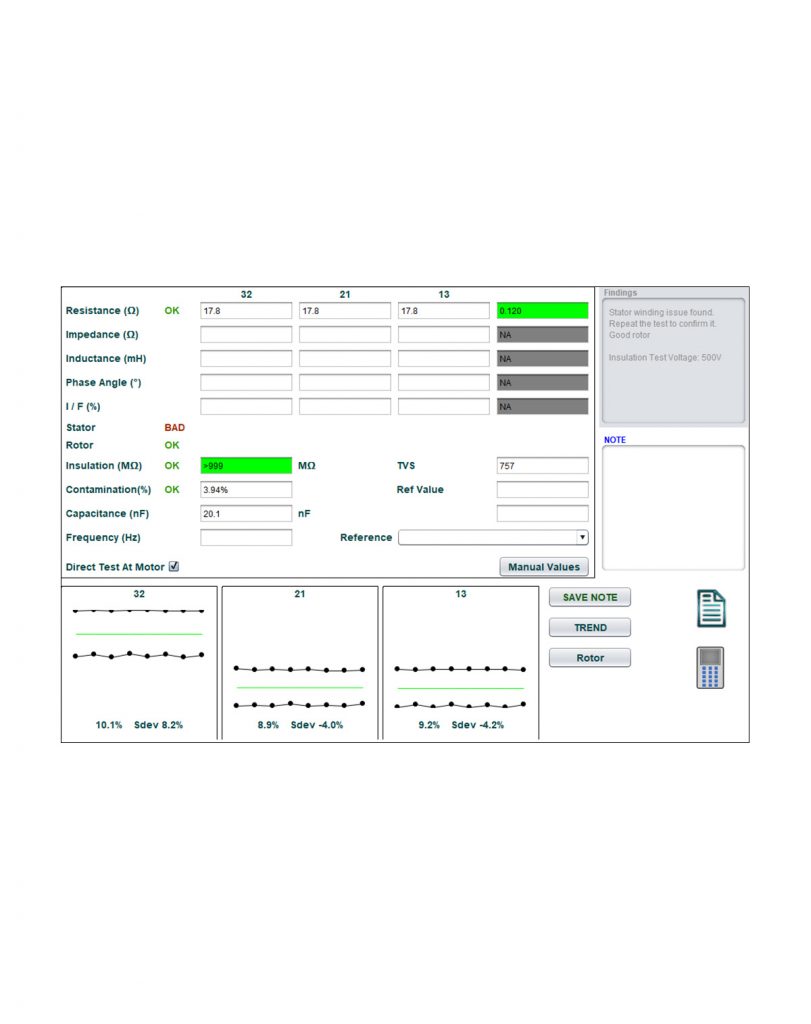

Motor Diagnostics for Troubleshooting

MCA™ Software applies proprietary algorithms and automatically diagnoses likely motor faults, taking the guesswork out of interpreting test data. The reporting feature displays a tabular and graphic view of the results which are easy to interpret and understand.

Motor Tending for Predictive Maintenance

All test data can be trend-graphed for condition monitoring. Condition based monitoring allows you to see deteriorating conditions that will need to be rectified in the near future. Planning for repairs and avoiding unscheduled downtime saves you money and time.

Scheduling and Review

- Review motor assets to be tested by date.

- Retest based on motor trend condition.

- Or retest based on alarms.

You are even able to record additional test data for each motor such as infrared, vibration and other technologies you currently utilize to track assets.

Manage Assets by Location

Records can be grouped by buildings or process by manufacturing sites and also by customer name and location for service organizations. The user can quickly identify equipment marked Bad, Warning or Testing Past Due and the location of each asset.

MCA™ SUITE OFFERINGS

MCA Basic™ Software

- Comes standard with the ALL-TEST PRO 7™, ALL-TEST PRO 34™ and ALL-TEST PRO 34 EV™

- Single and 3-phase AC motor testing

MCA PRO™ Software

- Comes standard with the ALL-TEST PRO 7™ PROFESSIONAL

- Single and 3-phase AC motor testing

- Series, shunt, and compound wound DC motor testing

- Transformer testing

- Individual coil testing (test and compare up to 4 coils)

- Unique Rotor Grading System (RGS)

- Create unlimited ‘routes’ and maintenance schedules for predictive maintenance and condition monitoring

- Routes can maintain up to 100 pieces of equipment, scheduled for testing

- Create, update and print work orders within the system

MCA PRO™ Enterprise Software

- All the features and functions of MCA PRO™ plus multiple user accessibility

- 2, 5, 10 & 25 user licenses available

- Remotely analyze and generate reports

- Shared database to view individual motor history from multiple sites

- Easily determine the reliability and quality of motor vendors

- Accessible to multiple users on a computer network infrastructure which is limited to the number of concurrent users based on the number of purchased user licenses.