EV Motor Tester

AT34 EV™

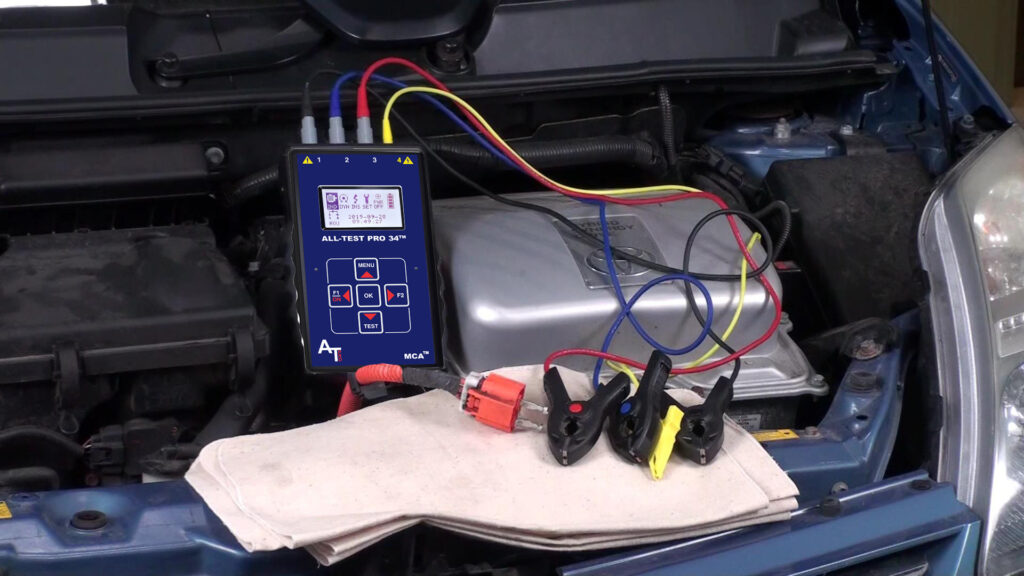

Deenergized Motor Circuit Analysis™ (MCA) Testing Instrument

Starting at $7,735.00 USD

The AT34 EV™ instrument is the only tool currently on the market for testing permanent magnet motors and generators used in electric & hybrid vehicles.

Features

- On-screen step-by-step testing instructions

- Tests take less than 3 minutes

- Static & Dynamic testing options

- Detects faults at the earliest stages before motor failure

Downloads

ADVANTAGES OF THE AT34 EV™

Detect issues in hybrid and electric car motors before motor failure occurs.

The AT34 EV™ electric and hybrid motor tester is the advanced permanent magnet motor and generator testing solution you need to keep your hybrid or electric vehicle motors running smoothly. Unlike other EV testing methods, the AT34 EV™ instrument allows technicians to test motors in vehicles without taking the motor apart.

With preventative testing, you can eliminate the otherwise inevitable time and money loss that comes with electric vehicle motor failure. Our electric vehicle testing equipment helps you detect problems with a vehicle’s stator, connections or rotor, all from a user-friendly handheld device.

The AT34 EV™ instrument is also extremely portable, so whether you’re in the shop or in the field, you’ll have access to superior motor and insulation testing abilities.

Complete Motor Health Assessment

The electrical health of all motor components is evaluated including stator windings, rotor, contaminations, ground faults, and connections.

Patented Test Value Static™ (TVS™)

Test Value Static (TVS) is a sum calculated from the 3-phase MCA static test and is used as a reference value for the motor. Common types of faults in the rotor and stator windings will change TVS.

Patented Dynamic Stator and Rotor Signatures™

Used to evaluate the condition of the stator and squirrel-cage rotor in a single test. Perfect for testing new and repaired motors prior to acceptance.

USES FOR THE AT34 EV™

OEM vehicle on-board diagnostics may not provide comprehensive analysis methods necessary for determining the health of an aged EM or provide clarity of determining whether a problem resides within the EM or its Power Inverter Module (PIM) system. Since the cost of an EM or PIM system can result in thousands of repair dollars, identifying and determining the root cause of the problem is essential. Furthermore, the labor time required to identify and confirm the root cause of a problem can be extensive, adding to the already substantial part cost of the repair. And, if the systems are misdiagnosed, the parts and labor costs escalate significantly.

Determining electric transaxle or transmission state-of-health (SOH) or, confirming that a catastrophic event has occurred is becoming a more important aspect of the aftermarket service industry and those that analyze, diagnose, and service electric powertrains. As the aftermarket continues to become more of an option to hybrid owners for service, it also becomes more important than ever to ensure that determining SOH or, for confirming an electric motor-generator unit (MGU) has reached its end-of-life (EOL) becomes a repeatable and reliable process.

The AT34 EV™ is a superior test instrument for performing 3-phase EM testing and SOH analysis. One of the primary advantages of the AT34 EV™ tool is its capability of testing an EM rotor without the requirement of rotation. In summary, the EM can be completely tested statically. For the technician, this means that testing can be accomplished with the High Voltage system disabled and no road testing is required – all testing can be accomplished in the service bay. MGU sub-system testing: AT34 EV is capable of testing MGU rotor and stator SOH without rotating (spinning) the rotor (whether permanent magnet or induction EM).

Test Value Static™ (TVS™) – a dimensionless number comprised of using a sub-set of the aforementioned instrument testing parameters of Inductance, Impedance (AC Resistance), Phase Angle, and Current-Frequency Ratio and scrubbing the resulting metrics with a complex algorithmic analysis. The 3-Phase winding parameter test data is then calculated by software algorithms that provide a resulting numerical value to the user for determining 3-Phase MGU stator and rotor electrical and magnetic performance. The user compares the dimensionless number to a reference number (numbers provided with the tester) for determining numerically how far the tested MGU data has drifted (or not) from new MGU test data of the same type or generation of transmission. The TVS value also eliminates the need for rotating the MGU to test 3-Phase stator windings, rotor magnets or rotor bars, and shorting rings, etc.

The AT34 EV™ provides cutting-edge testing solutions that detect motor issues in vehicles before they turn into expensive problems. With this instrument, you can evaluate the health of a hybrid or electric vehicle motor all in one test. The AT34 EV™ motor test device evaluates all motor components in its assessment process, including the rotor, contaminations, stator windings, ground faults and connections.

This instrument features both dynamic and static test capabilities to give you a full picture of your vehicle motor’s health. In fact, the AT34 EV™ device is incredibly user-friendly, with on-screen instructions to guide you and your technicians through any static or dynamic motor testing process. Reading and understanding the test results is made simple and easy, and the diagnostic results are accessible from a single screen.

It’s hard to beat the versatility and comprehensive diagnostic power of the AT4 EV™ motor tester. Browse our product brochure below to learn more about the unique capabilities of our innovative vehicle motor testing solution.