Electric Motor Troubleshooting

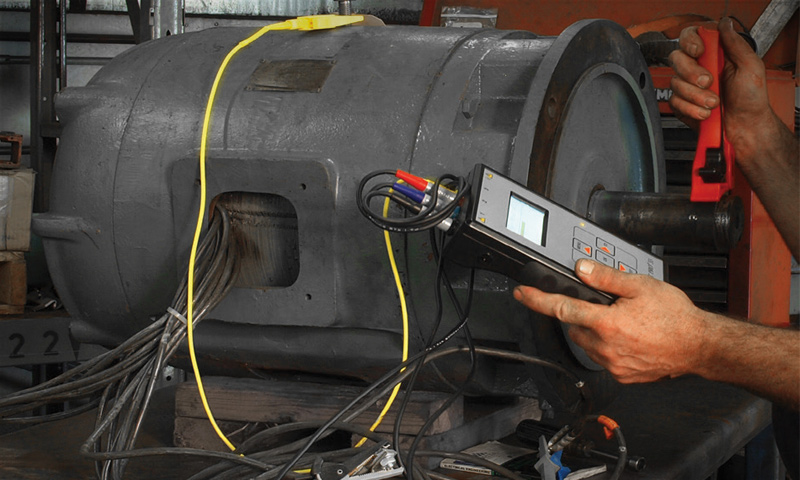

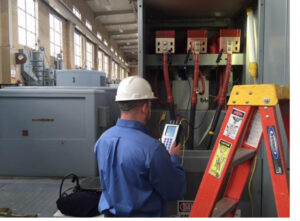

At ALL-TEST Pro, we are committed to bringing you the latest information and motor testing knowledge available. The information below contains in-depth tips on how to test an electric motor completely with deenergized and electrical signature analysis testing methods.

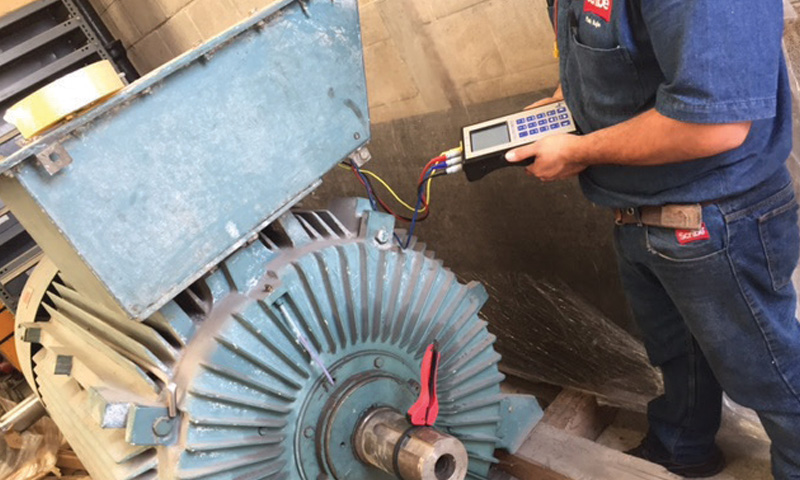

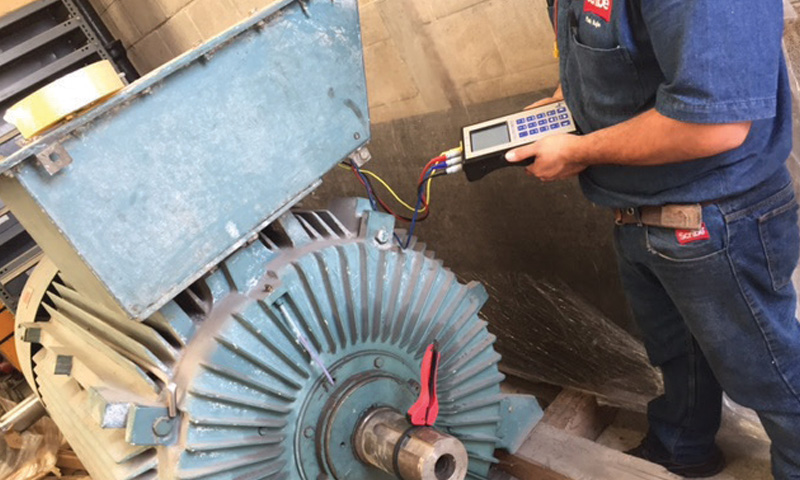

When a winding fault is detected from the motor control center or disconnect using MCA, a test must be performed at the motor, as motor circuit analysis measurements of Test Value Static, phase angle and current/frequency response, & insulation to ground can detect cable faults as well.

If the winding tests good at the motor, then the cable has a fault; If the test improves but a fault still shows, it is both a cable and winding fault; and if the test shows the same results at the motor, the fault is in the stator windings.

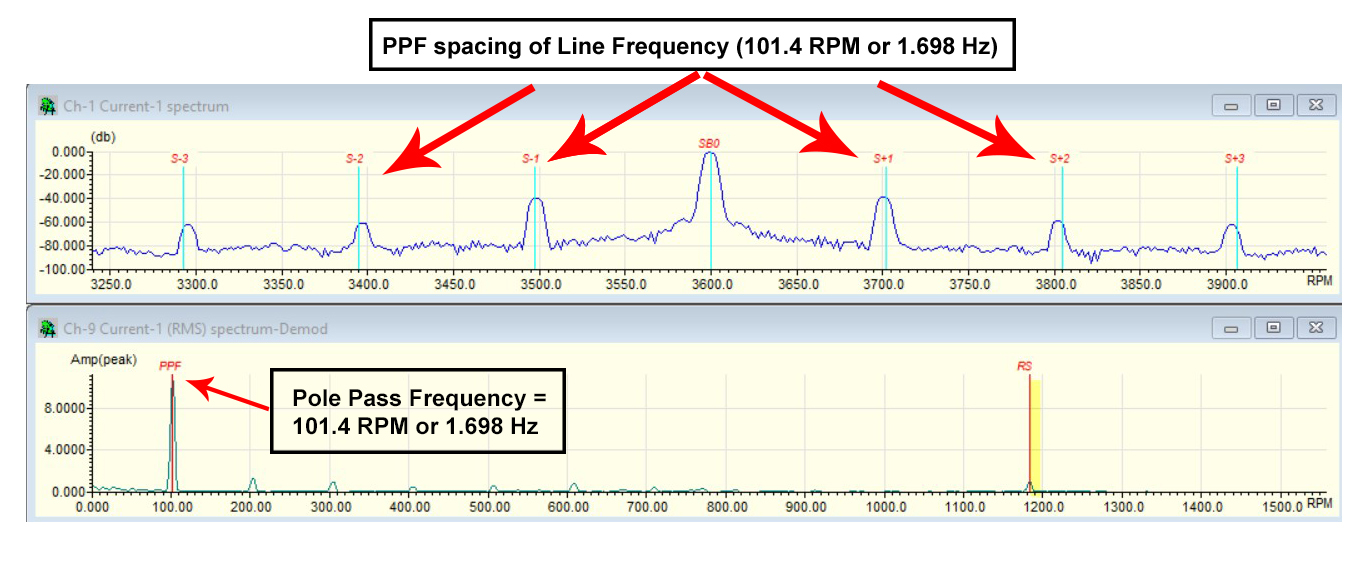

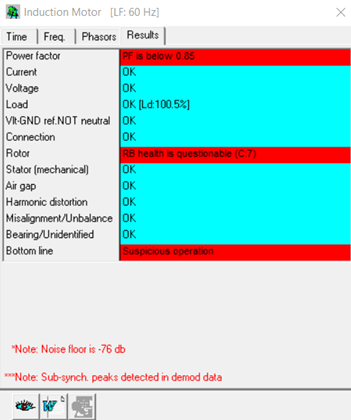

The multi-technology approach to motor diagnostics means you are utilizing different testing technologies that will complement and validate each other. One example is your vibration technician suspects a possible rotor problem in a critical application, but the cost to replace means a shutdown of production, where the motor’s cost is small compared to the incurred costs of the

shutdown.

In a situation like this, many people would be reluctant to make the call for replacement, for if the diagnosis is wrong, the cost is very high. Therefore, this motor may be run to failure, due to the uncertainty of the diagnosis. In this case, to put the multi-technology approach in practice, use Electrical Signature Analysis (energized testing) to confirm or rule out the preliminary findings (bad rotor). If the shaft of the installed motor can be turned or the load quickly disconnected, then a Motor Circuit Analysis test (deenergized) can be performed to assess the condition of the rotor, stator, and connections. By utilizing the multi-technology approach you will have more confidence in your findings and hence, a greater degree of certainty that you have determined the real fault(s).

Winding insulation degrades over time. MCA™ (Motor Circuit Analysis) detects these developing faults very early.Early detection of these faults allows for corrective action before they become catastrophic and result in a major rebuild or replacement.

These internal winding faults are the beginning of the end for most motors.Using Motor Circuit Analysis (MCA™) can help identify these types of internal winding faults. MCA™ is a deengerized test method and the test can be initiated from the Motor Control Center (MCC) or directly at the motor.

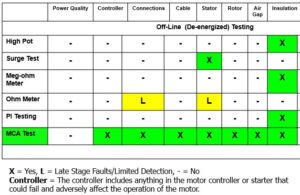

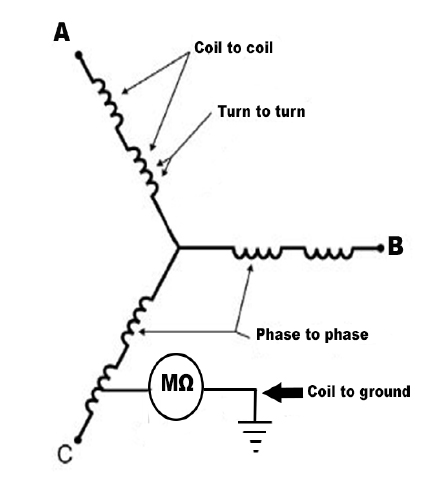

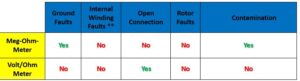

To a technician evaluating a motor, a meg-ohmmeter is like a Doctor’s blood pressure cuff. It is a measurement you have to make. It provides important information, and when it’s bad, it’s bad. But it is a one dimensional test, evaluating only the integrity of the insulation system to ground. By itself, it does not provide enough information to diagnose overall motor health. A high meg-ohm reading does not rule out motor electrical problems any more than a normal blood pressure reading rules out serious illness.

In addition, a meg-ohm test will miss inter-turn faults in the windings, it will miss poor connections, it can miss an open phase, and is totally unaffected by rotor problems. So should you measure insulation resistance? Of course, but recognize that much more information is needed to assess motor electrical health. Combining insulation resistance with other AC based tests such as Motor Circuit Analysis can give you a complete picture of motor electrical health,whether for troubleshooting or condition monitoring.

For AC Induction motors, winding failures can start and end as turn and coil shorts that do not break through the ground-wall insulation, regardless of the root-cause of the failure.Therefore, if you are only performing an insulation to ground test then you will miss these types of faults. Insulation to ground tests only detect resistive paths between the stator core and the conductors adjacent to the stator core.

Motor Circuit Analysis (MCA™) is a deenergized, non-destructive test that evaluates the condition of the motor connections, stator, and rotor. MCA™ testing can be performed from the output side of the motor starter or motor drive, therefore, no need to open up and disconnect phase leads at the motor for routine testing purposes.

An Ohmmeter is used to measure the electrical resistance between two points.A Micro-ohmmeter is used to measure low resistance circuits. A Megohmmeter is used to measure high resistance circuits. The unit of measure for resistance is an ohm.

When testing electric motors, it is useful to know the insulation resistance between motor winding(s) and the frame ground.This value will normally be in the range of tens, or hundreds or millions of ohms.

However, motor winding faults can also occur within the winding and is not detectable using the Meg or Micro-Ohm-meters. For these types of tests, other types if instruments must be used , such as the portable, light weight, hand-held, deenergized motor testers offered by ALL-TEST Pro.

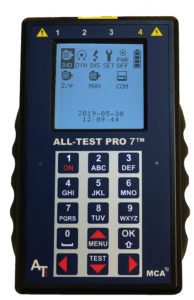

ALL-TEST Pro provides hand-held,battery operated, field portable test instruments designed to evaluate the entire electrical health of the motor. This included detecting developing coil-to-coil,turn-to-turn, and phase-to-phase short circuits before they become catastrophic. These instruments will enhance troubleshooting efficiency,improve your electric motor maintenance program, and help avoid unplanned production outages.

When a deenergized MCA™ motor testing program is first implemented it is not unusual to have between 10-30% of the motor systems tested to exhibit one or more alarm condition(s) when testing is performed from the output of the motor starter or motor drive. When a motor system is in an alarm condition, this does not necessarily mean that the motor will fail or that it should be stopped immediately, but that the measured values have exceeded predetermined limits.

One of the first considerations should be motor criticality. Obviously, the most critical motors should be afforded a higher priority than less critical motors. The second consideration is the type and location of the alarm (is it related to the connections, cable, motor winding, etc.?)

Our last MCA™ data analysis tip stated that it is not uncommon,for new users that begin a MCA™ motor testing program, to have between 10-30% of motor systems tested to exhibit some alarm condition. It is important to note that a motor system exhibiting an alarm condition should not be condemned(or the motor replaced), if the test was performed from the motor control center (output of the motor starter or motor drive). Motor connections and cables between the test point and the motor itself may be the root-cause of the alarm.

Therefore, the next step is to perform another test at the next connection point, whether a disconnect or at the motor itself,with incoming phase leads disconnected. If the alarm condition clears, then the problem is upstream of the test point. If the alarm persists then it is the motor. Lastly, non-repeatable test results should be considered suspect and investigated further.

Our last two MCA™ data analysis tips stated that it is not uncommon for new users that begin a MCA™ motor testing program can have between 10-30% of motor systems tested to exhibit some alarm condition. Tip 2 discussed the importance of performing additional testing to confirm the source of the alarm. I.e. is it related to connections, cables,or motor windings?

Moreover, with respect to AC induction squirrel-cage rotor motors <1000V, many new motors will exhibit an inductance and impedance imbalance, due to motor design/construction.Therefore, a healthy motor can exhibit an impedance and inductance alarm (even though it is in good condition). MCA™ measurements include impedance and inductance measurements, but phase balance is not used for assessing the condition of the motor windings.

An important distinction between RCL meters and MCA™ meters is the ability to fully exercise the entire winding insulation system. Using resistance alone, the I2R loss can be determined across a circuit, but the system electrical reliability, developing winding faults or efficiency cannot be determined. Inductance,which is variable, depending on the winding design and rotor to winding position* also can’t be used for these purposes.

Unfortunately, systems using inductance as a base will often fail good electric motors and windings. In order to obtain the true condition of a motor winding, one must view all of the motor circuit components, including resistance, impedance,inductance, phase angle current frequency response (I/F)and insulation resistance, DF & Capacitance to ground.

Motor Circuit Analysis™ (MCA™) is a deenergized, non-destructive testing method to assess the complete electrical health of a motor.

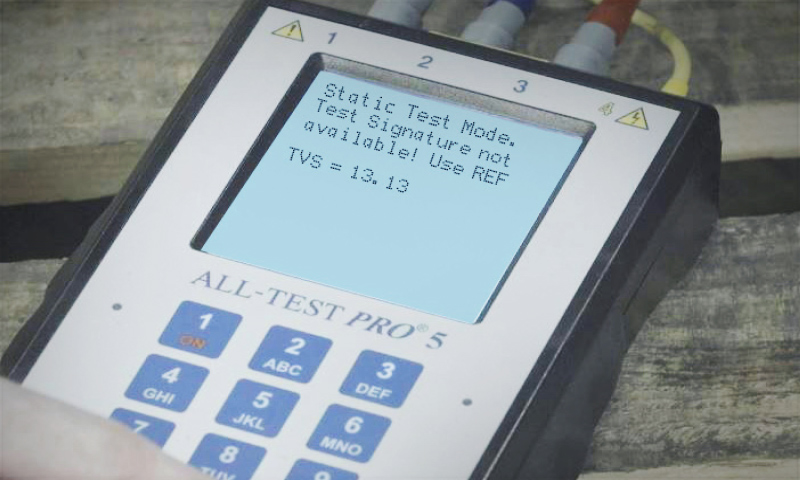

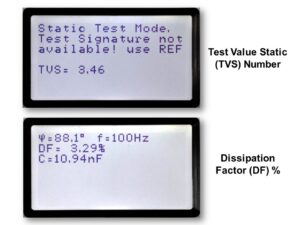

Patented Test Value Static™ (TVS™) is calculated from the 3-phase MCA™ static test and is used as a Reference value for the motor. Common types of faults in the rotor and stator winding will change TVS™. TVS™ is trended over a period of time to detect changes in the condition of the stator and rotor. TVS™ can also be used to compare motors of the same exact manufacture to insure you are receiving good, quality motors.

Traditional Megohmmeter testing will only detect faults to ground. Not all motor electrical stator winding failures begin as ground faults. Failures can start between turns in the same coil, between coils in the same phase, and phase to phase. If the only motor test you perform is with a Megohmmeter, you will miss detecting crucial stator and rotor faults.

Motor Circuit Analysis provides a complete view of the motor in just minutes. The test can be initiated from the Motor Control Center (MCC) or directly at the motor.

Motor Circuit Analysis is a deenergized, non-destructive testing method to assess the complete electrical health of a motor.

Motor Circuit Analysis (MCA™) uses three unique tests IND, Dynamic (DYN), and Z-Fi to test both the winding insulation and insulation resistance to ground. Dissipation Factor (DF), Capacitance (C) to ground, and insulation resistance to ground (INS) are used for testing the ground wall insulation. Capacitance is the capability of a body, system, circuit, or device to store an electric charge. DF is the ratio between the resistive power loss and the reactive power loss of the insulation material. This is used to detect contaminated or overheated windings. The primary reason for the INS test is safety. INS is performed by applying a high DC voltage between deenergized current-carrying conductors (windings) and the machine casing or Earth.

The IND Test Mode is used to test AC three-phase squirrel cage induction motors with rated voltage of less than 1000V. This test mode performs the Static and optional DYN tests on the winding insulation and insulation resistance to ground. Use the IND test during routine condition-based maintenance (CBM) on equipment that has a previously stored Test Value Static™ (TVS™) Reference. TVS™ reference values are a quick and easy way to determine if the motor condition is changing. The DYN test can determine both rotor and stator condition if the motor is decoupled from the driven load.

The Z-Fi Test Mode is used on all types of AC motors (of any voltage), generators, and transformers. The low voltage tests automatically perform all the Static tests: DF/C, INS, impedance, induction, phase angle, current frequency response (I/F), and calculates a TVS. The Z-Fi test mode

must be used on all medium or high voltage equipment (greater than 1,000V) and should be used on installed equipment with no TVS™ Reference. The reason the Z-Fi test is used on motors with no prior TVS is because you want to determine the current health of the motor. Once you generate a TVS™ value you can begin to trend the data. In the Z-Fi test mode you do not perform a DYN (dynamic stator & rotor test) because the load or drive is attached to the motor and the test is not practical.

Can you perform a DYN test in the Z-Fi mode? A DYN test is not offered in the Z-Fi test mode. Think of it as a baseline to find out what the condition of the motor is without a reference test. This equipment is usually already

installed without having the ability to rotate the motor shaft i.e. connected to gear box, submersible, or a pump.

Tracking your motor assets from “cradle to grave”; whether it’s routine maintenance, rewind or replacement, TVS™ keeps an eye on your motor assets and creates a culture of “Can Do!” that is easy to adopt at any facility where motors are present.

Any changes in the condition of the winding insulation or the rotor occur, it will be reflected in the TVS™. A technological advantage of implementing and using TVS™ is that it eliminates errors caused by inductance unbalances that can occur due to the position of a squirrel cage rotor. TVS™ is independent of rotor position. ATP has the only motor testing tools (instruments) in the world that provide a TVS™ value.

- TVS™ starts with either a baseline or an incoming inspection test on spare and replacement motors.

- The secondary and following TVS™ tests should be taken after the equipment is installed from the output controller or any easily accessible point. Subsequent readings should be taken from the same location and should be compared with the installed TVS™ value.

- Should the remote TVS™ value indicate an issue, another test direct from the motor should be taken. If the motor tests good, we know it’s the cabling to the control. If the motor is bad, generally we know the motor is bad and the cabling is good. Both could be bad, but it is rare.

Resistance testing in Motor Circuit Analysis™ (MCA™) is used primarily to find high resistance connections. These tests are taken directly at the motor junction box. A resistance test can reveal a miss-connected motor, or cold solder joints.

A phase resistance test performed in a Motor Control Center (MCC) or at a controller tests the entire motor circuit. This test can reveal high resistance connections in intermediate junction boxes, local disconnect switches and issues in the motor junction box itself. These high resistance connections generate heat, never get better, always get worse and almost always lead to unscheduled production losses.

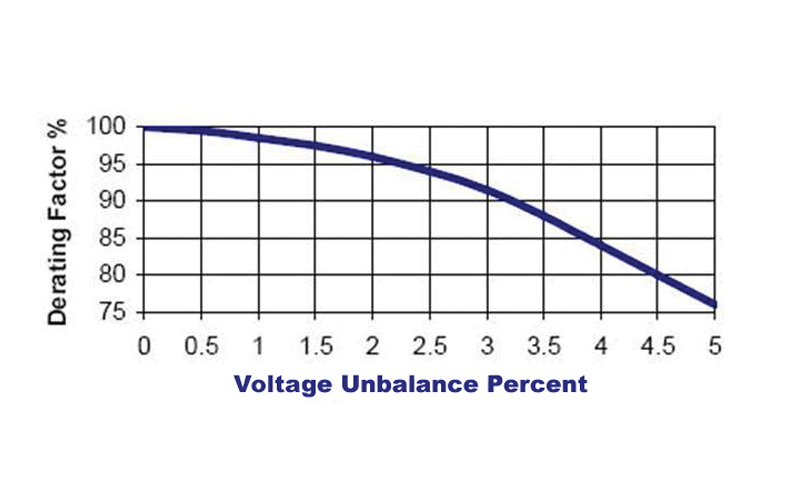

In addition to spot heat damage and potential phase to phase or phase to ground faults which can cause expensive catastrophic damage, high resistance connections cause voltage unbalances which in turn lead to motor overheating and decreased operating efficiency.

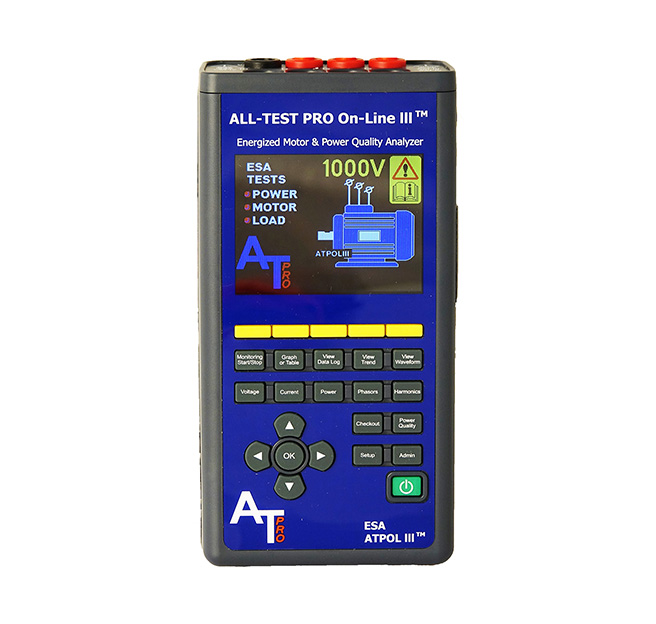

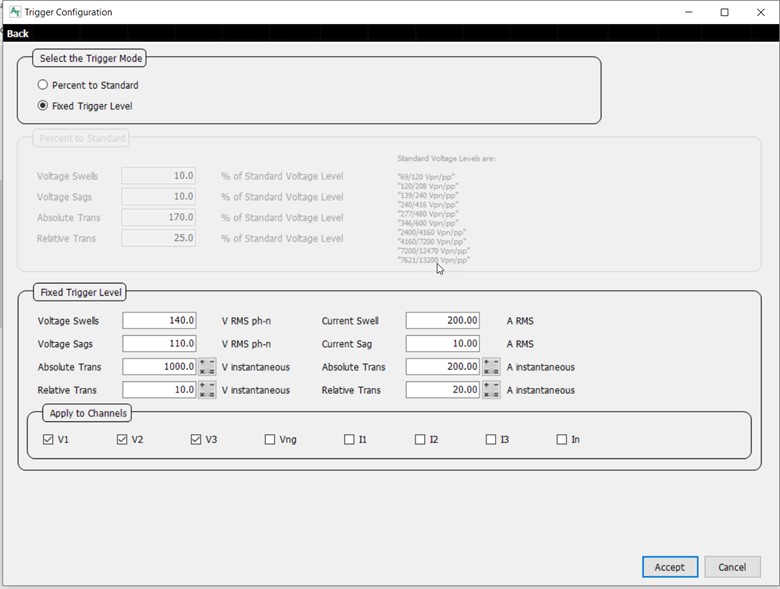

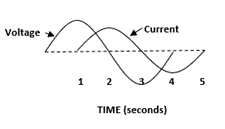

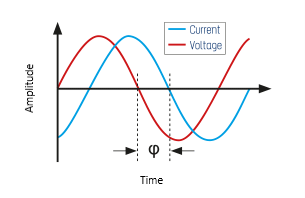

Electrical Signature Analysis (ESA) is an energized test method where voltage and current waveforms are captured while the motor system is running to assess the health of the motor system. Energized testing provides valuable information for AC induction and DC motors, generators, wound rotor motors, synchronous motors, machine tool motors, and more.

Motor Circuit Analysis (MCA™) is a deenergized test method to assess the health of the motor and motor circuit. This method can be initiated from the Motor Control Center (MCC) or directly at the motor. The advantage to testing from the MCC is that the entire electrical portion of the motor system, including the connections and cables between the test point and the motor is evaluated.

ALL-TEST Pro produces its ESA and MCA™ instruments as discreet, handheld, battery operated units that are all extremely field portable. The data analysis and storage elements are WINDOWs based and are easily shared between computers. Along with providing flexibility to a reliability department the use of individual instruments provides users with the ability to choose how much of which technology is best for their electric motor maintenance program. Both instruments & software provide dependable, quick answers so maintenance staff and managers can make reliable decisions and keep their maintenance team working simultaneously on different motor applications.

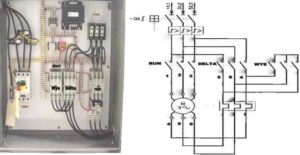

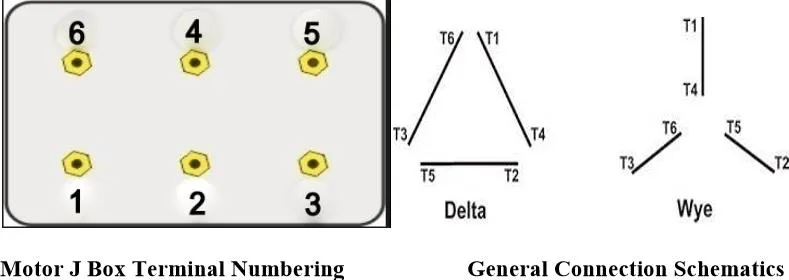

Testing At The Motor Junction Box: As with many motors a simple way to test the six lead motor involves going directly to the motor junction box. After confirming that all Lock Out / Tag Out requirements have been complied with and the motor leads have been checked for the presence of voltage, the motor junction box can safely be opened.

If the motor leads from the controller and the internal motor wires are labeled, make note of that connection. If they are not marked then mark them with colored tape or other identification so that they can be properly reconnected when testing is complete.

Disconnect the motor leads from the starter from the internal motor wires, or from the terminals in the box.

The internal motor wires or terminals should be numbered, one through six. As a check, you should be able to test for electrical continuity between terminals/wires 1-4, 2-5, and 3-6. These are your phase wires (A, B, C, or 1, 2, 3).

To test the motor in the WYE configuration you must short together terminals/wires number 4, 5, and 6. The wires can either be bolted together or significantly sized shorting jumpers used. The tester(s) can then be connected to terminals/wire numbers 1, 2, and 3. Only one INS to ground test is necessary in this configuration.

The 4, 5, and 6 leads need to be shorted together. This can either be done with jumpers at the bottom of the DELTA or WYE contactors or the WYE contactor can be somehow forced. With this shorting accomplished the instrument can be connected to cables 1, 2, and 3 at the the instrument can be connected to cables 1, 2, and 3 at the bottom of the RUN contactor.

The ALL-TEST PRO 7™ brings predictive maintenance to DC motor testing. Preventive Maintenance Tasks for DC motors such as commutator & brush inspections, lubrication, are very important for their long-term successful operation. However, these inspections fail to determine the condition of the electrical winding or insulation. Adding periodic electrical tests, such as measurements of the winding resistance and Insulation Resistance to Ground (IRG) provide some insight to possible connection issues & weaknesses in ground wall insulation, but still fail to determine the overall condition of the equipments insulation condition.

By adding MCA™ readings to DC motor testing provides early indication of developing problems within the motors electrical system beyond those detected using a megohm and ohm meter. MCA tests can be performed quickly from the drive and can confirm or eliminate faults in DC machines.

By adding MCA™ readings to DC motor testing provides early indication of developing problems within the motors electrical system beyond those detected using a megohm and ohm meter. MCA tests can be performed quickly from the drive and can confirm or eliminate faults in DC machines.

Several key points quickly determine the condition of DC Machines

- Take Series winding and armature windings readings together

- Test motors and generators the same

- I/F reading outside of the range of -15 to -50 indicates a winding fault

- An increase in temperature corrected winding resistance, accompanied by changes in impedance indicates loose connections

- A decrease in temperature corrected resistance accompanied by changes in impedance, inductance, phase angle & current frequency response (I/F) indicates developing winding shorts

- Deviations of phase angle or I/F of more than 2 points between like motors indicates the need for a MCA complete analysis

- Changes in MCA reading in the armature circuit between test intervals prompts a bar to bar armature test

- Changes in MCA readings in the armature circuit taken back to back indicates carbon build up in the armature

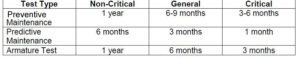

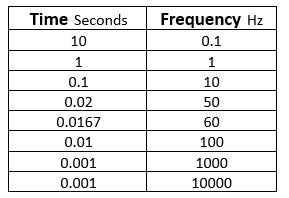

By following these simple guidelines using the AT7P™ provides early fault detection before the DC machine fails during operation. Recommended testing intervals should be at least those shown in Table 1.

Table 1: DC Motor Frequency

Once a developing fault is detected, it is recommended to reduce the time intervals between tests until the machine can be removed for repair. A complete armature test is recommended in conjunction with preventive maintenance tasks.

Conclusion

Preventive electrical testing of direct current machines is much easier using the DC mode function of the AT7P™. Step by step detailed easy to follow procedures are provided on the large backlit LCD display to make the testing quick and easy to perform from the motor drive in less than 5 minutes. Additional tests and features are available for troubleshooting at the motor to quickly pinpoint the source of the problem. MCA™ testing dramatically improves DC machine testing by saving time and providing more details as compared to traditional techniques and methods.

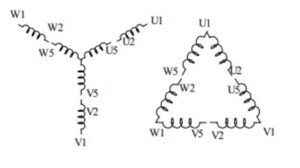

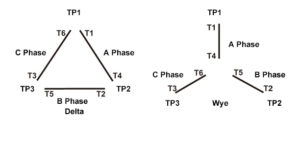

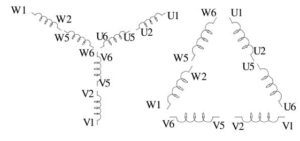

For MCA trending and analysis of three phase electric motors, three motor leads are connected to the MCA instrument. When new motors are tested the technician may encounter motors with multiple motor leads. This allows for the motors to be used in multiple applications. Normally the connection diagrams are provided by the Original Equipment Manufacturer (OEM). This guide is provided if the manufacturers diagram is unavailable. These guidelines do not supersede the OEM connections. Generally, the coils all use standard numbering schemes so connecting them for MCA testing is straight forward. It is assumed that the technician has basic electrical skills and access to the proper wire connections materials such as wire nuts, split bolts, lugs, assorted machine screws or bolts, and insulating materials that may be needed to make temporary or permanent connections to the motors under test.

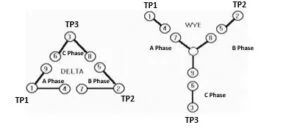

Three phase motor winding each have a start to the phase and the end to the phase. These phases are then connected in a DELTA or WYE configuration. Any unbalance in test results will show up regardless of the connected configuration. If the test result is to be used as baseline data, any subsequent testing should be done in the same configuration for trending and comparative purposes. A note about the test configuration can be entered into the relevant computer analysis

software test data file. Example- MCA PRO™ computer software.

Six Lead Motor Diagram

To test the motor in the DELTA configuration the start of each phase is connected the end of another, and the motor leads T1, T2 & T3 are connected to this junction of the phase leads. Firmly connect leads T1 to T6, T4 to T2, and T5 to T3 and use these connections as the test points 1, 2, and 3. To connect the motor in the WYE configuration, firmly connect the end of the phases together to form a “wye” connection and insulate leads T4, T5, and T6 and then use the start of the phases as the test points 1, 2, and 3 as phase connections.

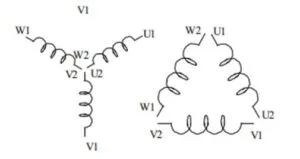

Six Lead IEC Motor Diagram

Nine Lead Motor Diagram

Nine lead motors will come from the OEM or repair facilities with some of connections internally connected in either a DELTA, or WYE configuration. To complete the connections, connect motor leads T4 to T7, T5 to T8, and T6 to T9 with wire nuts or other suitable means and use motor test points 1, 2, and 3 as phases connections.

Nine Lead IEC Motor Diagram

For MCA trending and analysis of three phase electric motors, three motor leads are connected to the MCA instrument. When new motors are tested the technician may encounter motors with multiple motor leads. This allows for the motors to be used in multiple applications. Normally the connection diagrams are provided by the Original Equipment Manufacturer (OEM). This guide is provided if the manufacturers diagram is unavailable. These guidelines do not supersede the OEM connections. Generally, the coils all use standard numbering schemes so connecting them for MCA testing is straight forward. It is assumed that the technician has basic electrical skills and access to the proper wire connections materials such as wire nuts, split bolts, lugs, assorted machine screws or bolts, and insulating materials that may be needed to make temporary or permanent connections to the motors under test.

Three phase motor winding each have a start to the phase and the end to the phase. These phases are then connected in a DELTA or WYE configuration. Any unbalance in test results will show up regardless of the connected configuration. If the test result is to be used as baseline data, any subsequent testing should be done in the same configuration for trending and comparative purposes. A note about the test configuration can be entered into the relevant computer analysis

software test data file. Example- MCA PRO™ computer software.

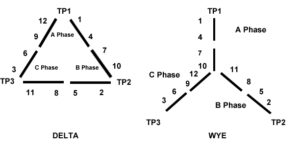

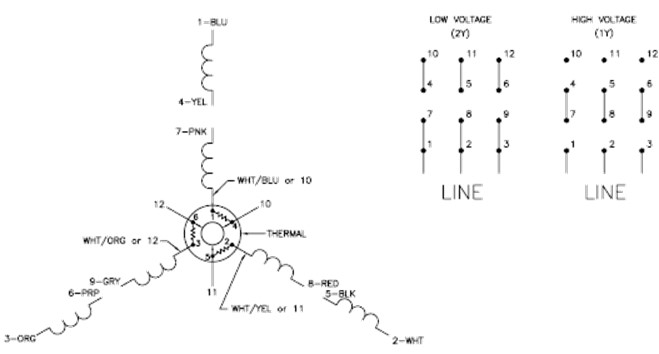

Twelve Lead Motor Diagram

Twelve lead motors offer the highest flexibility of any motor. They can be connected in a WYE or DELTA configuration, and are used for “high” or “low” voltage operation or multiple speed operations. However, this versatility does not complicate the testing procedure for testing motor spares or those motors returning from repair.

Twelve Lead IEC Motor Diagram

To test the motor in a DELTA configuration, firmly connect leads T1 to T12, T2 to T10, T3 to T11, T4 to T7, T5 to T8, and T6 to T9. Then use the pairs containing T1, T2, and T3 as phases 1,2, and 3 for testing.

To test the motor in a WYE configuration, firmly connect and insulate leads T10, T11, and T12. Then connect leads T4 to T7, T5 to T8, and T6 to T9 and use 1,2, and 3 as phases connections for testing.

There are other configurations which may apply for specific applications. For example: WYE start, DELTA run, or for high voltage or low voltage. For MCA testing the main importance is that all coils get tested during the test and the recommended connections accomplish this. If an unbalance is detected then individual coils can be tested as discussed below.

Individual phases or coils can be tested by performing single phase measurements from the start of a phase or coil to the end of the same phase or coil. For example, in a DELTA connected 12 lead motor, A phase can be measured from 4 to 9, B phase to 5 to 7, and C phase 6 to 8. For a WYE connected motor, A phase 1-10, B phase 2-1, C phase 3-12. Individual segments can be compared using single phase measurements of individual coils, 1-4, 2-5, 3-6, 7-10, 8-11, 9-12.

How to Tell If Electric Motor Is Bad

What do you do when a motor fails or trips a drive? What tools do you currently use to determine if the motor is “good” or “bad”? If you are like most technicians, you probably use a Megohm Meter and a Digital Multi-meter.

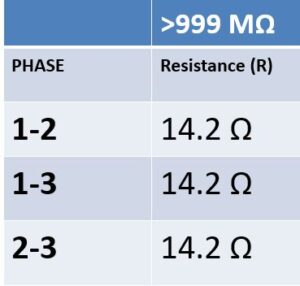

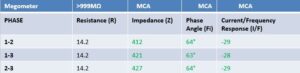

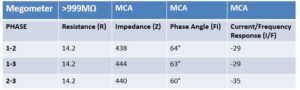

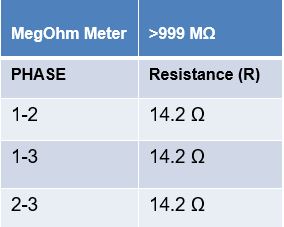

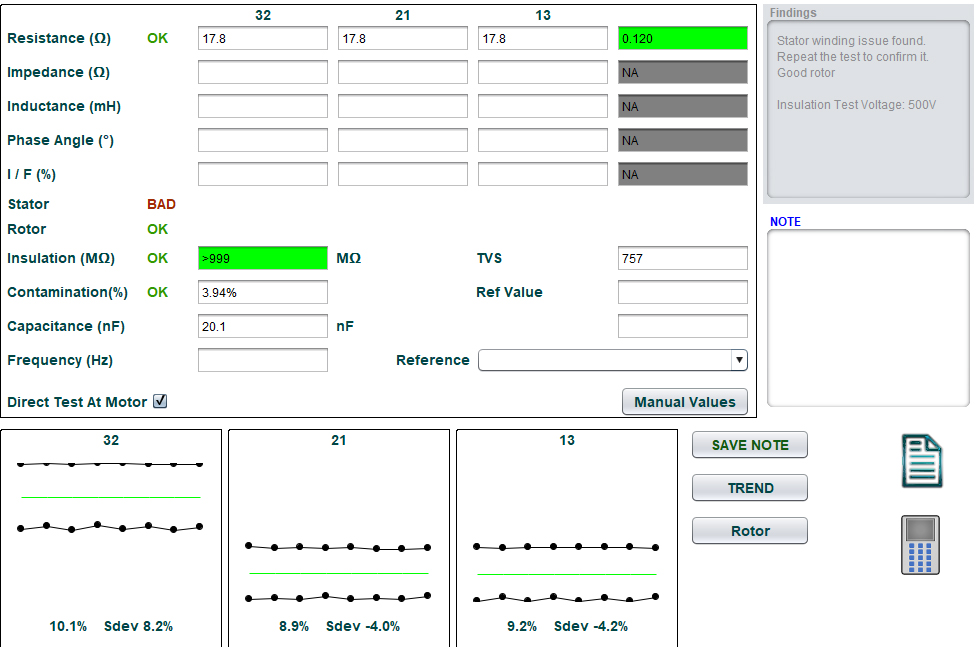

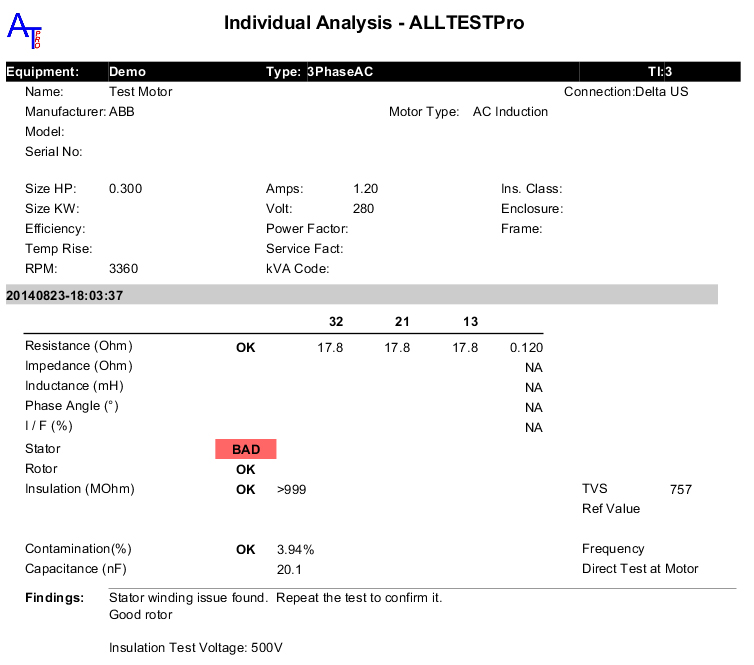

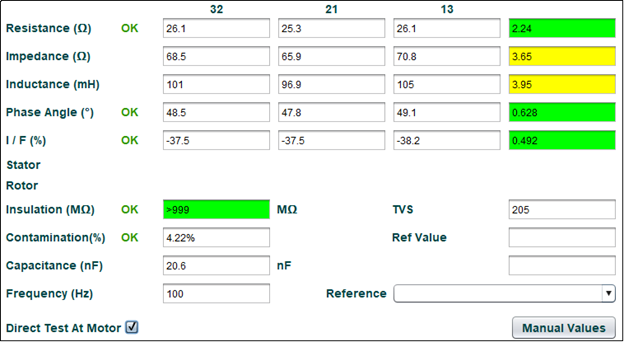

Looking at an actual motor test on an installed motor where the drive had tripped.

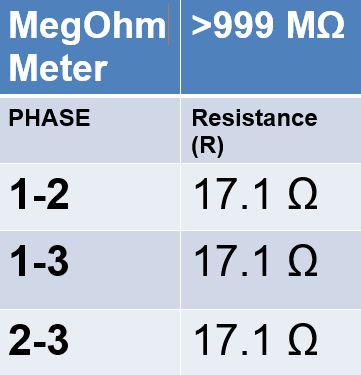

The electrician, using a Megohm Meter and Digital Multi-Meter, acquired these results.

So, what does this indicate about the condition of this motor? Based on these readings the problem is obviously, with the Drive and not the Motor, right? So,

what would you replace the VFD or the Motor? The service technician was relying on a megohm meter Insulation-to-Ground test which indicates that the ground wall insulation has no weaknesses to ground, and a Digital Multi-meter (Resistance test), which indicates there is continuity in the windings and all connections are good. The service technician was only looking at 2 factors that affect the motor. Both instrument measurements indicate that there is nothing wrong with the components tested but fails to provide a complete picture of the motor’s condition. As far as these instruments can tell this motor is in good condition.

These methods of testing are very reliable in determining if your motor is “alive” or “dead” (i.e., shorted to ground) or has connection issues, but will not give you the motor’s current state of health. Did you replace the Drive or the Motor?

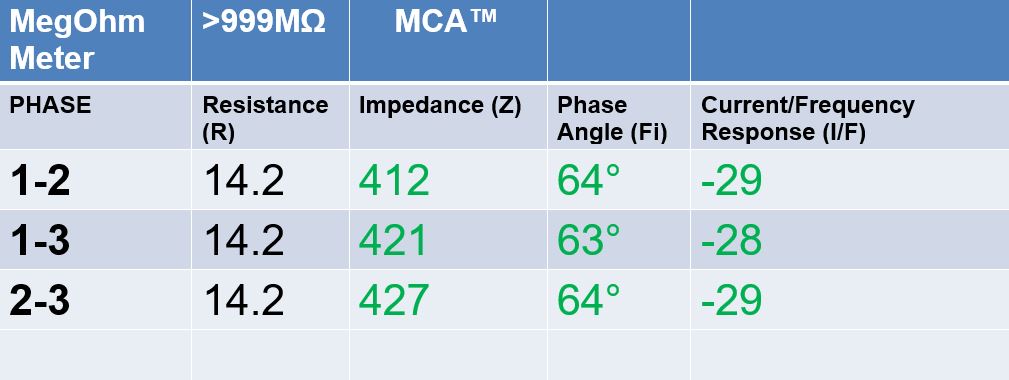

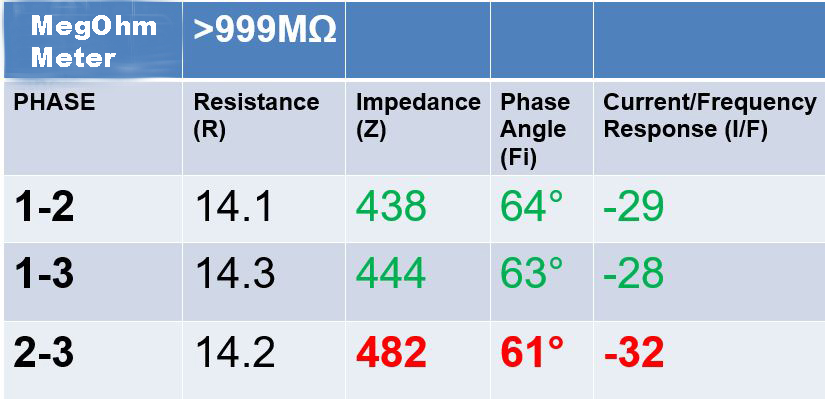

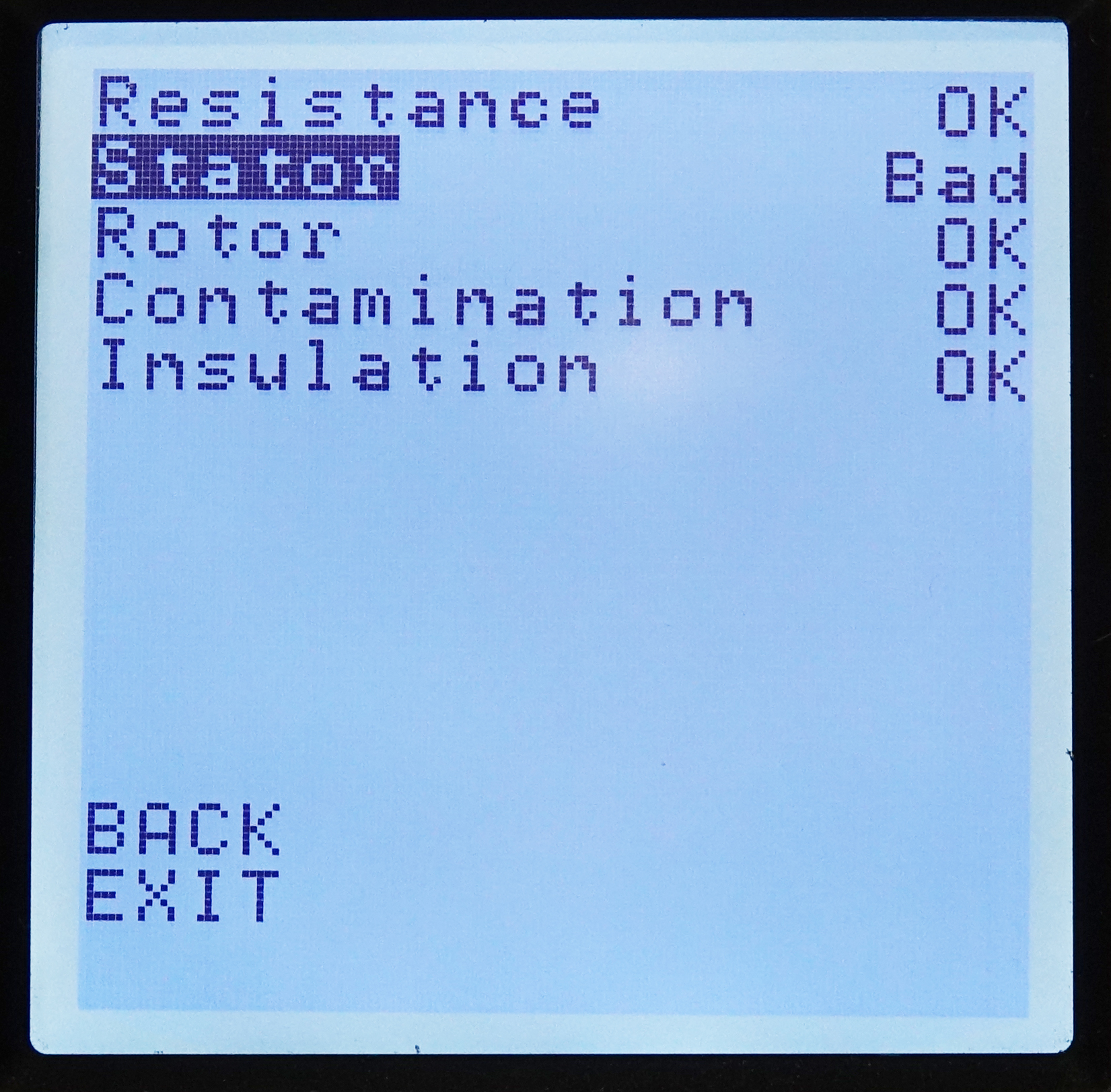

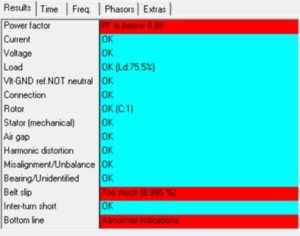

Using Motor Circuit Analysis™ (MCA™), this is what that same electrician found: by performing MCA™ testing. Phase angle (Fi) and Current/Frequency (I/F) both indicate no evidence of existing or developing winding shorts.

If you replaced the motor, you cost your company time and money, both in the cost of the motor and the fact that you will have to replace the drive when it trips again.

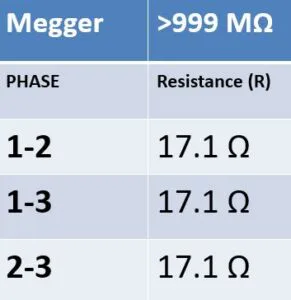

The same electrician had an identical motor trip the drive on a different line.

Now what? Is it the Drive or the Motor? If you said Motor, you are correct. Since these readings are the same as the on previous motor it would suggest that the motor is good so the fault must be in the drive.

The MCA™ instruments clearly shows unbalances in both phase angle and current frequency response which are indications of winding shorts. So in this case the fault is definitely in the motor.

MCA™ instruments offer fast reliable answers to motors state of health.

• Fast test under 3-5 minutes.

• Easy on screen directions.

• Answers displayed on screen as GOOD, BAD, WARN.

• Available with phone APP or MCA™ Software suites.

What are your motor testing tools measuring?

What is MCA™ technology? MCA™ (Motor Circuit Analysis) is a deenergized low voltage test method that exercises the motors winding insulation system to assess the health of the entire motor and the associated cabling.

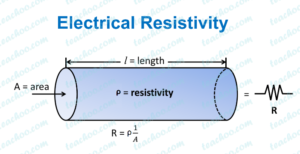

Resistance is a fundamental property of a materials ability to resist the flow of electricity through it. The units of resistance are ohms and uses the Greek symbol omega (Ω) and the mathematical symbol is (R). All materials have some amount of resistance, most metals have low resistance and are known as conductors. The Specific Resistance of a material is resistivity and is represented by (ρ). The resistance of a material is dependent on the type of material, the length and shape of the material. The resistance of an object or material determines how much work or heat is created as current flows through the material. For example, a material with a high resistance will consume a large amount of energy as current flows through the material. The current that produces work and creates heat is known as resistive current (Ir).

The resistance measurement is named after Georg Simon Ohm a 19th century, German physicist who studied the relationship between voltage, current, and resistance. He is credited for formulating Ohms’ Law which is the resistance of a circuit (R) is equal to voltage (E) applied to the circuit divided by the current flow (I) through a circuit. R = E/I

Materials in electrical circuits are classified as either conductors or insulators.

Conductors are materials that have loosely bonded electrons in the outer most shell of the atoms making up the conductive material and offer very little resistance to current flow. Electrons flow easily through conductive material. Examples of conductors are copper, steel, iron, bronze, and many other metals.

Insulators are materials that have very tightly bonded electrons in the outer most shell of the atoms that make up the insulating material and resist the free flow of current through the material. Insulators present a high resistance and restricts the flow of electrons. Examples include rubber, glass, wood, and many plastics.

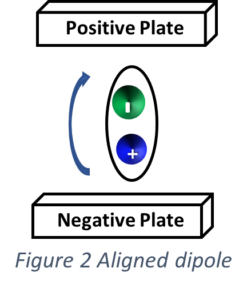

The fundamental of electricity is that current takes the path of least resistance, therefore insulators are used to direct the of current flow through the intended path and prevent the flow of current through unwanted paths.

In motors conductors are formed into coils or windings to create the magnetic field required to convert electrical energy into mechanical torque. To maximize the strength of the magnetic field current needs to flow through each turn of the winding. Therefore, the conductors that are used build the windings are coated with multiple layers of insulation to direct the current through the winding. This insulation is referred to as winding or turn insulation.

When the insulation between conductors begins to break down, current will still not flow between conductors until the resistance of the insulation falls below the resistance of the conducting material around the conductor. Therefore, the resistance measurement of the individual windings will remain unchanged until the insulation is has completely failed.

Resistance is directly proportional to the overall length of the conductor, the size of the conductor (in circular mills), and the temperature of the conductor. For example, it is much easier for water to flow through a wide, short pipe then it is for water to flow through a more narrow, longer pipe. Current through an electrical conductor reacts the same way. Current will flow much easier through a large, short piece of wire then it will through a more narrow and longer piece of wire, because there is less resistance of flowing electrons in the larger conductor than the smaller conductor.

Therefore, when measuring the winding resistance in a deenergized three phase motor electric motor, any resistance unbalance is usually the result of connection issues. The resistance of all three phases should be balanced in relationship to each other. Any unbalance of 5% is a warning and indicates there are issues in the motor circuit.

When testing from the MCC a resistance unbalance could be anywhere from the connection in the MCC (Motor Control Cabinet), the cabling or the motor itself. Additional testing needs to be performed progressively closer to the motor to locate connections that are causing the unbalanced resistance.

If resistance measurements at the motor are balanced this verifies the issue is somewhere between the MCC and the motor cables. If resistance values directly at the motor are unbalanced this confirms there is an issue inside the motor. Examples of things that can cause unbalanced resistances are loose connections, cold solder joints either in the motor or at the MCC, frayed or broken wire, dirty terminals or oxidation of the connections anywhere in the motor circuit.

MCA™ is a field proven very easy to use and safe method of evaluating the condition of electrical equipment while the equipment is deenergized. The basic premise of MCA:

In equipment with three phase coils all phases should be identical. Consequently, all the electrical characteristics of the winding should be the same. If any change in the condition of insulation occurs, it is never good, (windings do not “fix” themselves). So, any change in the winding insulation system is “bad”. The phase coils have 2 separate and independent insulation systems The groundwall insulation system and the winding insulation system; the condition of one insulation systems doesn’t indicate the condition of the other, therefore each insulation systems needs to be tested thoroughly and independently. The groundwall insulation system isolates the coils from the equipment’s frame or other exposed parts of the equipment while the winding insulation system directs the current through the conductors to create the magnetic field. MCA™ performs a series of tests on both insulation systems.

Groundwall Insulation: Breakdown of the groundwall insulation system is a safety issue and requires immediate action. MCA™ measures the insulation resistance to ground measurement to locate any weaknesses in the groundwall insulation but doesn’t provide the overall condition of the insulation. Dissipation Factor (DF) and Capacitance to Ground (CTG) reading provide additional indication of the overall condition of the ground wall insulation system, but none of these provide any indication of the winding insulation system.

Winding Insulation: A breakdown in the winding insulation system will result in shorts between tuns in the windings which results in weakened magnetic field, unbalanced current flow, increased heating, and eventual atastrophic equipment failure. MCA™ performs a series test by applying low voltage AC & DC voltage to the three phase windings while the motor is deenergized. The DC voltage measure the winding resistance using especially designed Kelvin leads to provide very accurate winding resistance measurements to identify connection issues.

When the winding insulation begins to degrade, it undergoes a change in the chemical makeup of the insulating material surrounding conductors. The AC current flowing through the windings exercises the entire winding insulation. The very small changes that occur because of the chemical makeup are measured and evaluated. By analyzing the amount and relationships the causes and severity of developing winding failures can be identified and the proper action recommended.

MCA™ can be used for:

1) Incoming inspections on all new & repaired motors

2) Spares testing

3) Pre installation testing

4) Troubleshooting

5) Routine predictive maintenance testing

MCA™ Tests

Static Test – tests all three AC motors windings, performs a series of tests at different frequencies on all three phases of the motor’s windings from the motors line leads, T1, T2, T3. The results of the test are input into a proprietary algorithm to create the Test Value Static (TVS). The TVS is a dimensionless number that serves as a baseline value to defines the condition of the equipment. Any changes in this value > 3% indicates a fault. This value may be compared to other identical equipment (must be the same HP/KW rating, speed, frame size, and manufacturer).

Dynamic Test – is performed on squirrel cage induction motors < 1000 V. While the motor shaft is smoothly and slowly manually rotated, stator and rotor signatures are created. The stator and rotor signatures are automatically analyzed to identify and report faults in either the rotor or stator.

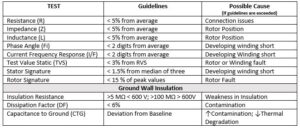

Phase Comparison Test – tests three phase coils in all types of three phase equipment, including motors, generators, and transformers. The phase comparison or “Z” test measures, DC winding resistance (R), impedance (Z), inductance (L), phase angle (Fi) and current frequency response (I/F).

The results of the tests are recorded and provided to determine any differences in the phases. These differences are compared to pre-determined guidelines created through many years of field testing the condition of the winding insulation. These values can be trended over time, used to determine the type and severity of developing fault, and provide an estimate of time to failure.

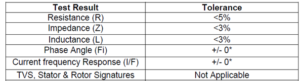

The following guidelines have been developed from over 35 years of field testing, but they are simply guidelines and are a good starting point, however, as with any guideline’s failure will not occur immediately if these guidelines are exceeded.

The basic procedures for MCA™ testing static and dynamic tests are performed all on new equipment to evaluate the new motors condition and establish base line or reference values for future testing. New baselines are established from the motor control center (MCC) once a motor has been installed. All future readings can be taken are if all measurements from the MCC are balanced all connections in the motor circuit are tight and the winding insulation surrounding the conductors in all the phases are in good condition. If an unbalance occurs, analysis and perhaps further testing may be same required to evaluate the type and severity of the fault. The AC tests measure impedance (Z), inductance (L), phase angle (Fi) and the current frequency response (I/F) to evaluate the condition of the winding insulation.

Experience has shown that 20 to 40 percent of motor systems tested may have some sort of alarm condition. Just because a motor has exceeded the alarm limits in MCA Basic™ or MCA PRO™ it does not necessarily mean the motor will fail or should be stopped immediately. For over 30 years the dedicated staff at ALL-TEST Pro have gathered data and resources to determine when a motor will most likely fail on the most common 3-phase squirrel cage motors. Some motors may have a special design that may cause the measured values to be outside the standard limits but still operate correctly. In some cases, even a brand-new motor can receive an inductance and impedance alarm due to the Rotor Bar/Winding ratio. The following analysis tips will help you determine when a motor should be condemned and should be taken out of service.

Never condemn a motor from the Motor Control Center (MCC). Faulty cables and bad connections between the test point and motor can cause unbalanced readings and produce an alarm. If an alarm is received at the MCC another test should perform directly at

the motor with the motor leads disconnected from the motor cables from the MCC. If the alarm remains, a problem with the cables and connections from the MCC can be ruled out and the motor can be investigated further. If the alarm clears, then the motor cables and connections should be inspected for possible failures.

Another thing to think about is what types of faults are identified during a test. Winding shorts are generally more severe than contamination or rotor faults. Developing motor faults are first indicated by changes between the baseline TVS value and a newly obtained TVS value, Stator Signature, or unbalances in Phase Angle (Fi) and Current Frequency Response (I/F). Motors that receive these faults should be taken into consideration before motors with inductance/impedance or resistance faults.

A motor should never be condemned from one test. If there is any residual voltage on the motor, you may get a result that could show a warn or bad alarm. It is recommended to take a second and even a third test of the motor to verify alarms. It is also important to isolate the motor from any other induced voltages from other electrical equipment while conducting a test. An induced voltage on the motor can cause inconsistent and unreliable readings that do not repeat. It is important not to condemn a motor that is giving unrepeatable readings because of this.

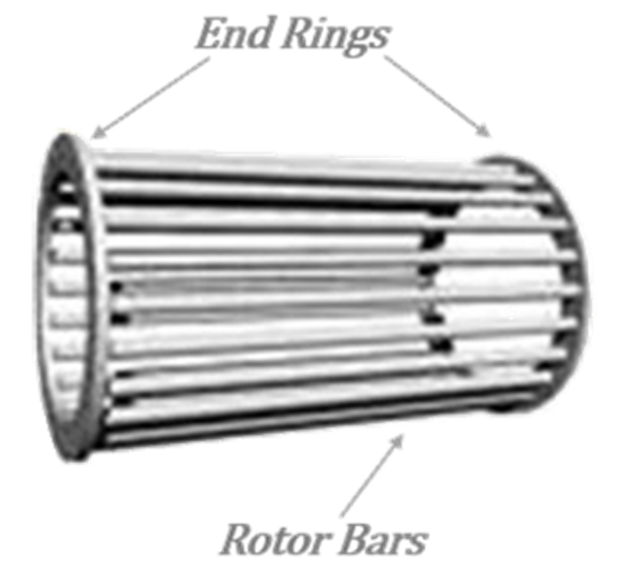

Induction Motors can be defined as a transformer with a rotating secondary. This is because power is induced from the stator electric circuit to the rotor’s electrical circuit. Three Phase AC power is applied to the stator windings and creates a magnetic field which rotates around the stator at constant speed. The speed is determined by the number of poles and the applied frequency. This magnetic field rotating around the stator induces an EMF (electromotive force) into the electrical portion (squirrel cage) of the rotor. The interaction between the magnetic fields on the stator and the rotor convert electrical energy into mechanical torque. This brief discussion describes these principles and how they affect MCA™ measurements.

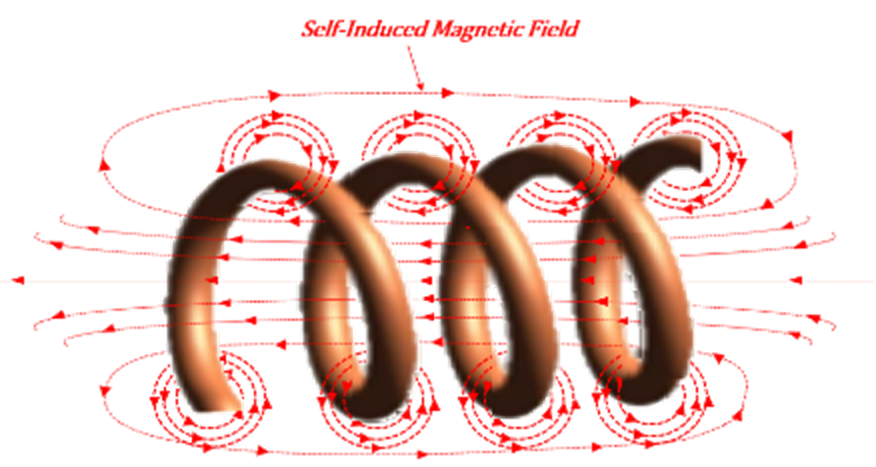

Inductance

Inductance is defined as the property of an electrical circuit or system that opposes any change in current. Inductance is represented by the Symbol L and the units are measured in Henry’s. The amount of inductance in a coil is dependent on the physical construction of the coil. The five physical characteristics that determine the inductance of a coil are:

1) The number of turns in the coil; the inductance increases as the square of the increase in number of turns.

2) Diameter of the coil; the inductance is directly proportional to the cross-sectional area.

3) Length of the coil; the inductance is inversely proportional to the length of the coil. The further the turns

are separated the lower the inductance.

4) Number of layers in the coil; the more layers the more inductance.

5) Permeability of the core material; the higher the permeability of the core the more inductance.

There are 2 types of inductances:

1. Self-Inductance is defined as the induction of an EMF (voltage) in a current-carrying conductor, when the current flowing through the conductor is changing. The magnetic field is created by the current in the circuit itself and induces a voltage in the same circuit. An inductor stores energy in the form of magnetic fields and opposes a change in current.

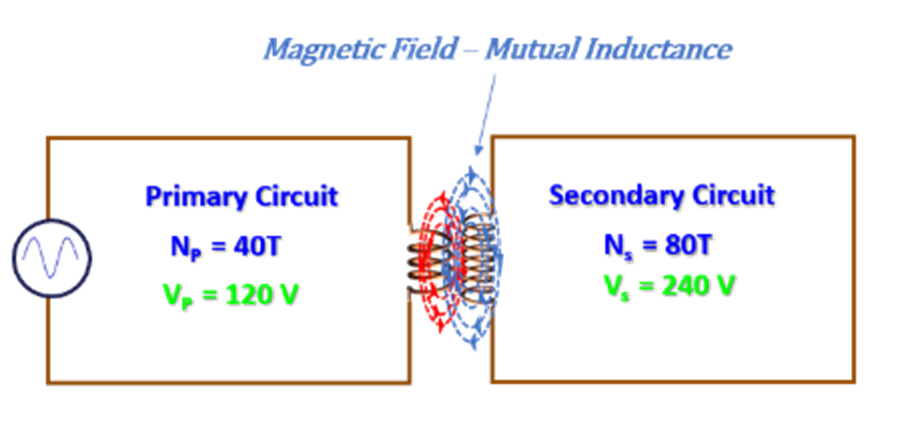

2. Mutual inductance is the EMF created when the magnetic field, created by current flowing through one circuit, intersects conductors in another circuit. Faradays law, states that when a changing magnetic field from the primary circuit intersects the conductors in the secondary circuit it induces a voltage in the secondary circuit.

A transformer is one of simplest electrical devices and are perhaps the best example of mutual inductance. The circuit with the AC source is the primary side of the transformer. The circuit in which the magnetic field is induced into is the secondary. A transformer exhibits all the principles of mutual inductance. Transformers effectively changes voltage from one circuit to another by changing the number of turns in each circuit.

For example, if the primary coil has fewer turns than the secondary coil, the magnetic field in the secondary will be stronger than in the primary and the induced voltage of the secondary will increase. This is a step-up transformer.

Equation 1: Transformer Ratio – Vp/Vs = Np/Ns

Vp = Primary Voltage Np = Number Turns in the primary

Vs = Secondary Voltage Ns = Number Turns in secondary

AC Induction Motors

Defining the AC induction motor as a transformer the stator winding act as the primary of the transformer and primarily establishes self-inductance. During operation the rotating magnetic field relies on Faraday’s law of mutual inductance to induce an EMF into the electrical portion of the rotor which is the squirrel cage. The squirrel cage consists of cast or fabricated bars (rotor bars) that provide the path for current required for mutual inductance.

operation the rotating magnetic field relies on Faraday’s law of mutual inductance to induce an EMF into the electrical portion of the rotor which is the squirrel cage. The squirrel cage consists of cast or fabricated bars (rotor bars) that provide the path for current required for mutual inductance.

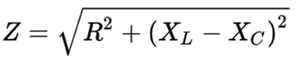

Inductive Reactance (XL)

By definition, inductance opposes a change in current, this opposition to the changing current reduces the current flow through the conductor and is known as inductive reactance. X is measured in ohms.

Equation 2: Inductive Reactance – XL = 2πfL

Where: f = frequency L = inductance

Therefore, if the applied frequency or either the self or mutual inductance increases, the XL will increase.

Impedance (Z)

Impedance is the comprehensive resistance in a circuit and consists of DC resistance, inductance reactance and capacitive reactance. The symbol for impedance is Z and the units are ohms (Ω).

In AC induction motors the R (resistance) is produced by the resistance of stator winding, the XC (capacitive reactance) comes From any C (capacitance), created by insulating material between the conductors in the stator windings. However, most of the Z comes from the large contribution of inductance created by self–inductance of the stator coils and the mutual-inductance between the stator coils and the rotor bars.

In AC induction motors the R (resistance) is produced by the resistance of stator winding, the XC (capacitive reactance) comes From any C (capacitance), created by insulating material between the conductors in the stator windings. However, most of the Z comes from the large contribution of inductance created by self–inductance of the stator coils and the mutual-inductance between the stator coils and the rotor bars.

Motor Circuit Analysis™ ( MCA™)

Motor Circuit Analysis™ applies a series of low voltage AC and DC signals to the motor’s stator windings. If the coils are all the same, the response to these signals should be all the same or “Balanced”. Generally, any changes in the condition of the winding insulation will cause one or more of these measured values to change. However, due to the design and position of rotor inside the stator the MCA™ results will show an unbalance in the L (inductance) and Z (impedance) measurements in the phases even on motors in perfect condition. The MCA™ Software and AT7™ will provide a “WARN” indication when any of the phase’s L or Z deviate by more than 5% from the average of the three phases. This WARN doesn’t necessarily indicate a developing or existing fault but could be the result of “Rotor Position” which is addressed in the rotor reposition test below.

When testing a motor that is currently installed in a machine it is good practice to conduct a test directly at the Motor Control Cabinet (MCC). Not only are you testing the health of your motor, but you are also testing for problems in the motor’s cabling assembly as well as connection points at the MCC and at the motor. If an alarm is received while conducting a test with one of ALL TEST Pro’s deenergized instruments at the MCC than the next course of action would then be to conduct a test directly at the motor with the motor cables disconnected.

Depending on if the alarm clears or stays you are then able to pinpoint the location of your alarm between the MCC and the motor. If an alarm is received at the MCC and is consistent at the motor, then it is confirmed the motor is the root cause of the problem. If you receive an alarm at the MCC and it clears directly at the motor, then the cause of the alarm lies between the MCC and motor cables.

Depending on if the alarm clears or stays you are then able to pinpoint the location of your alarm between the MCC and the motor. If an alarm is received at the MCC and is consistent at the motor, then it is confirmed the motor is the root cause of the problem. If you receive an alarm at the MCC and it clears directly at the motor, then the cause of the alarm lies between the MCC and motor cables.

Some potential problems could be:

• Fraying and weakening of cable insulation material

• Poor or loose connections either at the MCC or motor

• Contaminated/oxidized contactors at the MCC

Always remember to make multiple tests at each location to confirm repeatability and accuracy of your test results.

For decades, ALL TEST Pro has been an industry pioneer in offering easy to use, portable, and battery-operated instruments for all your deenergized motor testing needs. In some facilities it can be quite challenging finding a standard 120-volt AC outlet to connect a device to, even more so if an extension cord is needed to reach the location where testing is being performed.

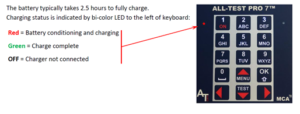

The most important thing to remember with a battery operated instrument is to keep it fully charged while not in use. It may seem simple, but nothing is more frustrating than needing to conduct a motor test, but you must wait because the battery is fully discharged.

The most important thing to remember with a battery operated instrument is to keep it fully charged while not in use. It may seem simple, but nothing is more frustrating than needing to conduct a motor test, but you must wait because the battery is fully discharged.

It is recommended to keep the instrument on the charger when not in use because of this. The battery will slowly discharge while sitting idle so if you do not use the instrument for an extended period the battery will eventually fully discharge and not turn on. While the instrument is plugged into the supplied charger the charging circuit in the instrument will automatically turn on once the battery falls below the preset threshold. Meaning there will not be power on battery if it is at full charge. Lithium-Ion batteries do not develop memory and don’t require full discharge before charging. To increase the life of the battery it is recommended to perform more frequent partial discharges instead of a full discharge. Make sure to only use the supplied charger with your instrument as using an aftermarket or 3rd party charger can damage the charging circuit and or battery if the charger has the incorrect polarity or supply voltage.

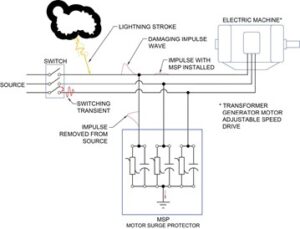

Many medium to high voltage electric motors are equipped with a Capacitor bank or Surge Arrester to protect equipment from unexpected transient power surges due to external lightning strikes, internal switching events or other transient voltage surges. These devices are crucial to protect equipment that could easily be damaged by these unexpected surges in power. When conducting a motor test with one of ALL TEST Pro’s line of deenergized motor testers it is particularly important that these capacitor banks or surge arresters are disconnected and isolated from the motor.

These capacitors and surge arresters will filter test results and create incorrect and inconsistent readings which can lead to false diagnoses of the motor. When testing a motor with a capacitor bank or surge arrester it is recommended to take a test directly at the motor with the incoming motor cables disconnected. You can also disconnect the motor cables at the load side of the capacitor bank or surge arrester and conduct a motor test at that point. Always remember to conduct multiple tests before condemning a motor to verify consistency of results. Please refer to the Motor Circuit Analysis manual for more details on condemning criteria.

These capacitors and surge arresters will filter test results and create incorrect and inconsistent readings which can lead to false diagnoses of the motor. When testing a motor with a capacitor bank or surge arrester it is recommended to take a test directly at the motor with the incoming motor cables disconnected. You can also disconnect the motor cables at the load side of the capacitor bank or surge arrester and conduct a motor test at that point. Always remember to conduct multiple tests before condemning a motor to verify consistency of results. Please refer to the Motor Circuit Analysis manual for more details on condemning criteria.

Not only is MCA (Motor Circuit Analysis) a great way to determine developing winding faults of a motor at the earliest stage but it also can be used to pinpoint the exact location of a fault in a motor system from the MCC (Motor Control Center) all the way to the motor. One of the most crucial factors to find early-stage faults is conducting two baseline tests when installing the motor. The first baseline test should be performed directly at the motor completely disconnected from any motor cables or other equipment. Future tests can then be compared and trended to this baseline test to look for changes which will signify a motor fault.

Once the motor is installed into the machine a second baseline test should be performed directly from the MCC. This will establish a baseline test all the way from the MCC to the motor and again can be referenced when taking future tests.

With both baseline tests it will be quite simple to determine the exact location of a fault if a motor is starting to fail or intermittently tripping a drive or circuit breaker. First a test should be performed directly at the MCC and then compared to the initial reference test from the MCC.

If there is a deviation between test results or a WARN or BAD indicator is displayed on the results screen the technician should then conduct a test directly at the motor with the motor cables disconnected. If there is still a deviation between the new test and the initial baseline test taken directly at the motor or a WARN or BAD indicator the technician can conclude the motor is the root cause of the failure and should be addressed appropriately. If the deviation between tests clears and no WARN or BAD indicators are established, then the motor cables and connection points at the MCC can be investigated further until the root issue is found.

(MCA™) Motor Circuit Analysis™ takes the guesswork out of rebuilt and new stock motors. By performing a quick, less than 3-minute motor test as soon as a motor arrives, you can put your mind at ease knowing the motor is perfectly healthy and will function properly once installed or you can reject the motor directly at the shipping dock if it fails to meet your criteria.

Depending on the application, a motor install can take up to an entire day of work so performing a test prior to installation eliminates the chance of the motor not working properly. The process and goals are the same for rewound or new motors: save time, ensure safety, get the replacement installed the first time & improve morale. Never again go through the struggle of a tough motor installation to just to have to pull it out because the motor trips as soon as power is applied. By implementing this single strategy your company will save money and prevent unnecessary extra work by installing and uninstalling a defective motor.

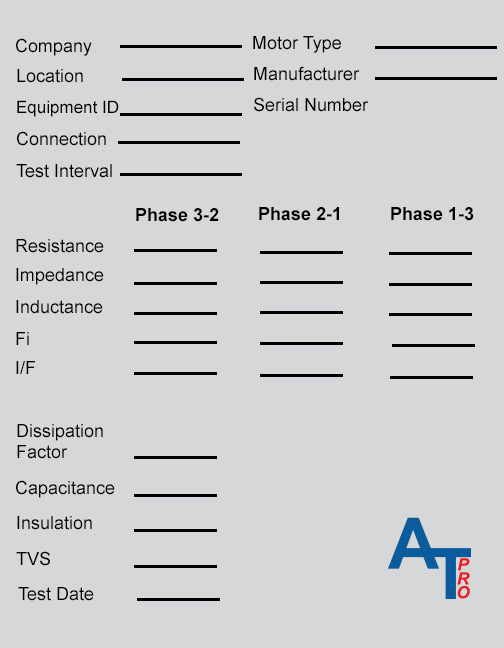

MCA™ is used to test inbound and outbound motors (new and used). Motor tags with MCA™ information help communications between vendors and customers as well as maintenance staff. MCA™ determines the motor’s health and status eliminating motor inventory ambiguity whether a motor is being shipped outbound (vendor or customer) or being received inbound for stock or immediate use.

(MCA™) Motor Circuit Analysis™ takes the guesswork out of rebuilt and new stock motors. By performing a quick, less than 3-minute motor test as soon as a motor arrives, you can put your mind at ease knowing the motor is perfectly healthy and will function properly once installed or you can reject the motor directly at the shipping dock if it fails to meet your criteria.

As early as the 1960’s, many companies realized that by routinely monitoring the operating condition of rotating equipment it is possible to obtain an advanced warning of operational or other problems that would impact continued efficient operation. This early warning provides time to remove the machine from operation and affect minor repairs and adjustments before catastrophic failures occur.

This maintenance philosophy, referred to as Predictive Maintenance (PdM), has escalated since the early 1980’s, with the introduction of microprocessor-based data-collectors. Many of the machines’ operating characteristics, such as temperature, pressure, oil condition, vibration and performance can be trended to identify changes. However, one of the glaring holes in predictive maintenance has been the inability to identify faults easily & accurately within electrical equipment, such as motors, transformers, solenoids and other like equipment. One of the main reasons for this was the lack of available easy-to-use predictive maintenance instruments for testing motors or other electrical equipment.

Predictive maintenance instruments should be:

• Hand-Held

• Easy to use

• Provide easy to understand answers

Implementing Predictive Maintenance Implementing a successful predictive maintenance program requires a complete understanding of the PdM process. Successful predictive maintenance consists of three phases – Detection, Analysis and Correction.

Successful predictive maintenance consists of three phases – Detection, Analysis and Correction.

Detection The detection phase involves periodically monitoring the operating characteristics of the selected equipment. These values are trended, compared to previously recorded data from that machine or similar machines, then compared against pre-determined or published standards and/or reviewed for any change.

During the detection phase, the data collection process should be done quickly and carefully, with the intent of

monitoring as many machines as possible. When a change is detected, additional data may be necessary, to

determine the cause of the machine’s condition change. This is done during the analysis phase.

In most cases, the Motor Circuit Analysis™ (MCA™) data taken during the detection phase may be sufficient to

identify developing shorts or other winding issues. But at times, additional data or testing needs to be performed

to identify the problem more accurately.

It is usually a waste of time to perform these tests for a more detailed analysis during the detection process, as it slows down the detection process. Most experienced predictive maintenance departments have recognized the importance of separating these two processes.

Analysis The analysis process involves taking additional and perhaps different types of tests than the detection process. This additional testing may require disconnecting the motor from the load, turning the shaft, or separating the motor leads and requires more time to take the data. Since usually only a few machines during the detection inspection exhibit any significant change, it is usually more time effective to only take the data necessary to identify a change during the detection process, and then go back for a more detailed look once a change is detected.

Analysis The analysis process involves taking additional and perhaps different types of tests than the detection process. This additional testing may require disconnecting the motor from the load, turning the shaft, or separating the motor leads and requires more time to take the data. Since usually only a few machines during the detection inspection exhibit any significant change, it is usually more time effective to only take the data necessary to identify a change during the detection process, and then go back for a more detailed look once a change is detected.

However, if the plant site is remote or has other access limitations, these may justify more detailed data be taken during the detection process.

Correction The correction phase involves correcting and eliminating the problem that triggered the analysis. This may require cleaning a motor, tightening connections, or a complete motor rewind. The exact type of correction and repairs are determined by the analysis.

The financial investment to implement an MCA™ testing process starts as little as $5,500 USD depending upon motor type and your needs. You will improve rotating equipment reliability by finding the defects early when your company can plan and schedule the outage versus experiencing the pain of machinery failure when least expected. You will improve maintenance staff productivity by equipping your technicians with the correct tools to perform their job in an efficient, safe & accurate manner.

The motor and associated cabling have service factors to consider for your process environment as does the equipment you use to monitor your uptime.

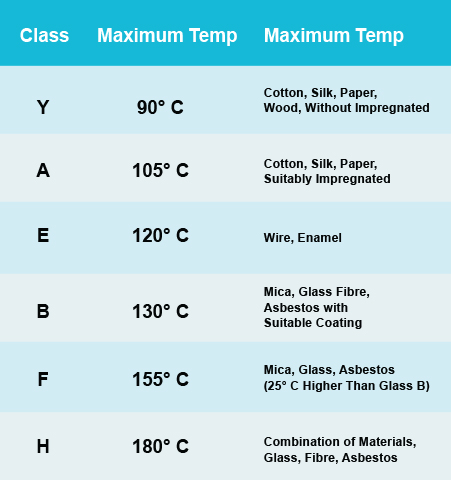

Variables to consider when replacing your motor and cabling are operating environment temperatures, conditions of process (wet, dry, dirty, etc.) and the process load. Ambient temperature at the facility may increase during the process phase of the activity. Over time the heat will transfer to other parts of the motor. Motor insulation classifications help determine the requirements for the optimal motor insulation to operate at a temperature rating for a specific operating lifecycle. This is the rise in temperature above the ambient temperature of the process environment to a maximum.

A given rating does not determine that an electric motor will run forever rather, it means that the insulation used on the motor winding should not fail at specific temperatures and then age and degrade as normal over the life of the motor. At some point the insulation reaches a point where the applied voltage is no longer able to be contained and a short or open winding may occur. NEMA (National Electric Manufactures Association) develop technical standards for electrical equipment and rates motors as Class A through H. An A rated electrical motor being lower temperature (105 degrees Centigrade) and H (180 degrees C) being the highest temperature with specific temperature rises and hot spots (center point of the motor’s winding where the temperature is higher). Having the correct motor insulation for your environment is critical for uptime. Arrhenius equation states that chemical reaction rates double for every 10° C temperature increase. Operating motors above the maximum temperature rating will rapidly degrade the life of the insulation and the motor life.

Environmental conditions have a direct impact on your motors. Starting with the right motor and cabling help ensure uptime. To understand, track or trend the condition of motors and cables, ATP recommends the use of MCA™ technology.

Environmental conditions have a direct impact on your motors. Starting with the right motor and cabling help ensure uptime. To understand, track or trend the condition of motors and cables, ATP recommends the use of MCA™ technology.

Motor Circuit Analysis™ tests all cabling, connections and electrical motor, without advanced electrical knowledge, use of multiple test points, and excessive time (test motor at motor control or at motor in under 3 minutes). MCA™ can determine motor health (rotor& windings), cabling and connection issues, VFD issues, and other troublesome issues that cause motors to fail, stop, run intermittently, and cause process problems. MCA™ is the only field proven, patented electrical technology in the world that can find early winding faults in motors, generators, transformers, or any coil in their earliest stages before they begin to cause problems.

MCA™ fully exercises the winding insulation system to identify

the slight changes in the winding insulation system occur over time. To determine winding health, MCA™ measures multiple standard electrical measurements of resistance, inductance, impedance, currency frequency response, phase angle, dissipation factor, resistance, and capacitance to ground to evaluate both the winding and the groundwall insulation systems. MCA™ uses a proprietary algorithm to create a single value, TVS, that defines the condition of the winding and rotor system. Changes in the TVS indicate changes in the motor and the motor’s health. The patented MCA™ dynamic test can be performed by simply manually rotating the motors rotor while the motor is deenergized to create the (dynamic rotor signature) & the stator (dynamic stator signature). This test can be performed on the plant floor to determine the status of the rotor & winding in 3 conditions, OK, Warn, or Bad. MCA™ automatically evaluates the condition of the motor using easy to follow on screen instructions. Testing the motors remotely from the MCC locates developing faults in the cabling, motor or even faults in the controller.

Testing the motors remotely from the MCC locates developing faults in the cabling, motor or even faults in the controller.

Electrical equipment operating in an explosive environment must be designed to prevent arcing or high temperatures that could be a source of ignition in this atmosphere. Motors that are designed to operate in these environments generally have an explosion proof rating. Motors selected for these applications should ensure the maximum surface temperature of the selected motor be lower than the ignition temperature of the area in which it is placed.

Within industry, all explosive and flammable atmospheres have been classified into zones for IEC motors and Division, Class and Group for NEMA motors. In either case, considerations are dependent on temperature and the nature of explosive or flammable material the motor would be operating near.

It is up to the end user to ensure the motor is installed, maintained, and operated in a way that does not pose any risk of ignition in the specified zone. One area of concern is selecting the correct XP motor to operate with VFD’s. When operating XP motors on VFDs, motors can challenge or even subvert many of the protective features built into XP motors. For example, motors that operate successfully on 50 or 60 Hz sinusoidal inputs may not maintain the same operating characteristics when connected to VFD’s.

Changes in the motors operating characteristics are caused by output voltage waveforms created by the PWM (pulse-width modulation) that controls and varies the speed of the motor. The output of the drives create steep voltage rises which can be reflected due to long cable runs from the drive to the motor. These reflected voltages can cause the voltage at the motor terminals, (as much as 250% higher) than the supply voltage. Additionally, the PWM signal creates harmonics in the voltage supplied to the motor which causes additional internal heating.

Additional surface temperature increases occur as the motor speed decreases. This is a result of the decreased cooling air flow coming from the cooling fan. The first law of fans is the volume flow rate is directly proportional to the shaft speed. Therefore, if the fan is directly attached to motor’s rotor, the air flow across or through the will decrease proportionally with a decrease in the shaft speed. XP motors which may be rated to operate in a hazardous area at rated speed may result in dangerous conditions when operated at reduced speeds.

Any condition that results in increased surface temperatures can create problems in explosive atmospheres. If a VFD is required for an XP motor, it is necessary to select the proper motor & VFD combination. Operating XP motors on VFD’s begins with selecting the correct motor/drive combinations that takes into considerations the ambient condition, supply voltage, frequency, motor speed & load, type of load as well as the zone and group. It is important to only use XP motors that are certified for variable speed operation within the temperatures and speed ranges of the hazardous zone they are placed in.

Figure: Wiring configuration for the motor with internal thermal sensors

A common protective feature for XP motors is internal temperature sensors in the motor windings that shut the motor down in cases of over-temperature. If the motor reaches the predetermined temperature limit, the motor will shut down. As the motor cools the thermal sensors may automatically reset or need to be manually reset. If the thermal overloads need to be manually reset the user will know why the motor failed, however, with automatic resets the fault of the shutdown will be unknown, and the motor will run again.

MCA™ (Motor Circuit Analysis™) will confirm the condition of the motor winding and verify VFD trips are being caused by the thermal trips and not degradation of the winding’s insulation. Performing a static test and comparing the current TVS to the RVS can quickly confirm the overall condition of the motor. A dynamic test performed by manually rotating the shaft will provide a more thorough evaluation of the electrical portions of the rotor and stator. A Phase comparison or Z test can quickly evaluate the condition of the winding insulation.

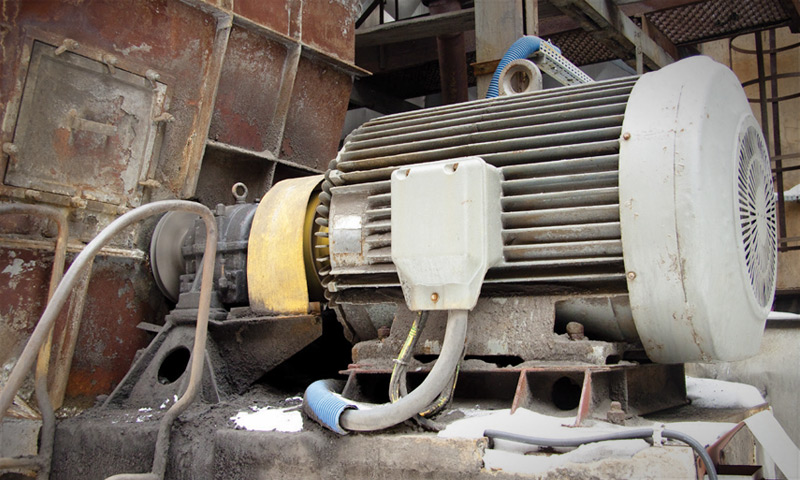

Motors age differently based on application, load, usage, the plant environmental temperatures, humidity, and contamination issues related to the motors process. Common issues with motor failure are bearings, stator winding, and rotor issues.

Over the last 5 decades predictive maintenance programs (PdM) have taken the forefront in plant environments with a large population of rotating equipment. The majority of the machines in these plants are driven by electric motors. Yet, the majority of PdM technologies are unable to evaluate the condition of the electrical portion of the motors.

The most common motors used in these applications are 3-phase squirrel cage AC induction motors, generally < 1000V supply voltage. These are the motors that the TVS™ is designed to quickly test, evaluate and report the condition of the electrical portion of these motors. The TVS is the only method available to deliver this very important detection phase of the PdM process.

TVS™ is a patented test method within MCA™ that

utilizes the various measurements proven (more than 35 years in the field) to identify the condition of the insulation surrounding the conductors which make up

the coils in the motor winding system or rotor issues. TVS™ tracks the life of a motor asset from receipt, installation to decommissioning or repair (cradle to grave). TVS™ is an acronym for TEST VALUE STATIC™, which is a measurement derived after performing an MCA™ Static test. This number when compared to a baseline test is a powerful indicator for faults developing in the electrical portion of either the rotor, stator windings or both. The initial TVS™ test is converted to the RVS, or Reference Value Static.

The RVS is the number which future TVS™ numbers are compared against. RVS values can be saved for each individual motor in the instrument or uploaded to the MCA™ software for storage and analysis.

Establishing the average TVS™ for known good motors of the exact motor type (manufacturer, model, with same manufacturing tolerances, etc.) can be used to assess the condition of all new or rebuilt identical motors.

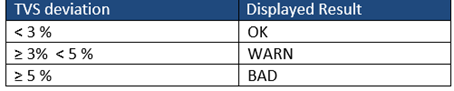

When a new TVS™ number compared to the RVS number varies by more than a 3%, either the instrument or MCA™ software will provide a warning indication. A warning indicates the condition of the motor is beginning to degrade, which could be in either the winding insulation or the rotor electrical system.

If the current TVS™ deviates from the RVS by > 5% the instrument or MCA™ software will provide a “Bad” condition signifying that severe degradation has occurred in the electrical portion of the motors winding or rotor system.

Static Test – is a patented test that performs a series of low voltage measurements on all three phases of squirrel cage induction motors at 5 different frequencies to define the condition of the motor with a single number. The results of the series of these tests are the input for a proprietary algorithm to create a single number which is the Test Value Static™ (TVS™). The TVS™ defines the condition of the electrical portion of the motor windings insulation system as well as the electrical portion of the squirrel cage rotor.

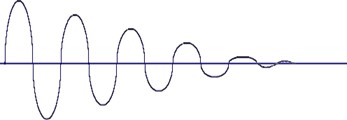

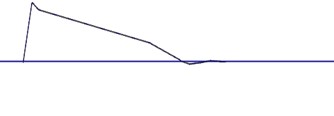

Dynamic Test – is a patented test that measures and records the impedance of each phase as the motor’s rotor is manually rotated smoothly and slowly. The user manually rotates the shaft uniformly with the aid of an automated beeps transmitted from the instrument to maintain the cadence on the rotation speed. The % in change of impedance is calculated by the instrument while the rotor is being manually rotated. The stator and rotor signatures display the changes for each phase while the rotor is being rotated. This test can determine if the developing fault is located in the winding insulation system (Stator) or the rotor electrical (Rotor) or both. Unlike the Static test, the Dynamic Tests can evaluate the condition of 3 phase squirrel cage induction motors with a single test.

Both the “Static” Test and the “Dynamic” test’s unique patented methods have eradicated errors associated with the rotors and stator fields relative positions thereby eliminating the need to perform additional “Rotor Compensated Tests” to confirm the fault.

The (IND) Industrial test (on the ![]() instrument) accesses the static, dynamic, insulation resistance to ground (IRG), DF (Dissipation Factor), and capacitance to ground tests (CTG). Motors should never be condemned using a single TVS™.

instrument) accesses the static, dynamic, insulation resistance to ground (IRG), DF (Dissipation Factor), and capacitance to ground tests (CTG). Motors should never be condemned using a single TVS™.

IND (Industrial Test) – are a series of tests performed within the MCA™ technology suite that accesses all of the measurements required to quickly and completely assess the condition for 3 phase squirrel cage induction motors < 1000V. The IND test provides the screens and instructions to performs the static and dynamic test. This test can be performed as part of the entire motor health check or isolate and locate developing faults if dictated by the test results.

The IND test also provides the displays and instructions to test and evaluate the ground wall insulation (GWI). Combining insulation resistance (IRG) & capacitance (CTG) to ground with the dissipation factor provide a more complete evaluation of the condition of GWI than the IRG measurement by itself.

https://alltestpro.com/resources/tech-tips.html#1607023307349-49097e7c-539b

How to Use TVS™ Static:

Static Test “RVS Solo” – This is the static test taken directly at the motor. All new and rebuilt motors should have the complete suite of IND tests including a static and dynamic test performed before accepting the motor from the supplier or repair facility.

The dynamic test will confirm the motor is in “Good” condition or locate faults in the electrical portions of either the stator or the rotor sections. If the dynamic test is good, this confirms the motor is in a “good” condition. This test is saved as REF.

Any changes in the electrical condition of the motor will be reflected as a change in the TVS. All future testing of the motor simply requires performing the Static test and comparing the resultant TVS™ to the stored RVS for that motor, if the current TVS™ < 3% the condition of the motor is the same as when the RVS was performed. If the results are 3%≥ TVS™ < 5%, degradation in the electrical portion of the motor is occurring. If the TVS™ >5% from the RVS a severe fault is detected, either in the rotor or the stator. At this point a dynamic test needs to be performed to determine if the degradation is occurring in the stator or the rotor.

Static Test Remote “RVS Remote” – Before a motor is placed in a system. A static test should be performed and compared to the RVS “Solo”. If the change is < 3% then the condition is the same as it was when it was new. After the motor is placed in service perform a Static test from the MCC (motor control center) and Save as REF, this is the RVS “remote” value. This new value will include the effects of all of the components in the MCC, & cabling from the MCC to the motor. (Note, this doesn’t confirm the cabling or the electrical components of the MCC are fault free, but it defines the condition of the entire electrical system (from the MCC through the motor).

Now any future readings can be taken from the same location in the MCC as the RVS remote was collected. Compare these “current” values to the stored RVS remote, using the same guidelines >3% & > 5% are used to evaluate the entire electrical system from the MCC through the motor.

Now any future readings can be taken from the same location in the MCC as the RVS remote was collected. Compare these “current” values to the stored RVS remote, using the same guidelines >3% & > 5% are used to evaluate the entire electrical system from the MCC through the motor.

If a fault is developing isolating to the motor or the cabling, simply requires performing a Static test at the motor and comparing it to the RVS Solo. If these values are less <3% then the fault is either in the cabling or the electrical portion of the MCC. However, if the “current” TVS™ >3% from the RVS solo, then a fault is developing inside the motor. At this point it is recommended to conduct a dynamic test to isolate the fault to the rotor or stator.